Slicing Software for 3D Printers: Achieve Perfect Prints Every Time

Are you tired of spending hours perfecting your 3D prints, only to end up with less than satisfactory results? Look no further.

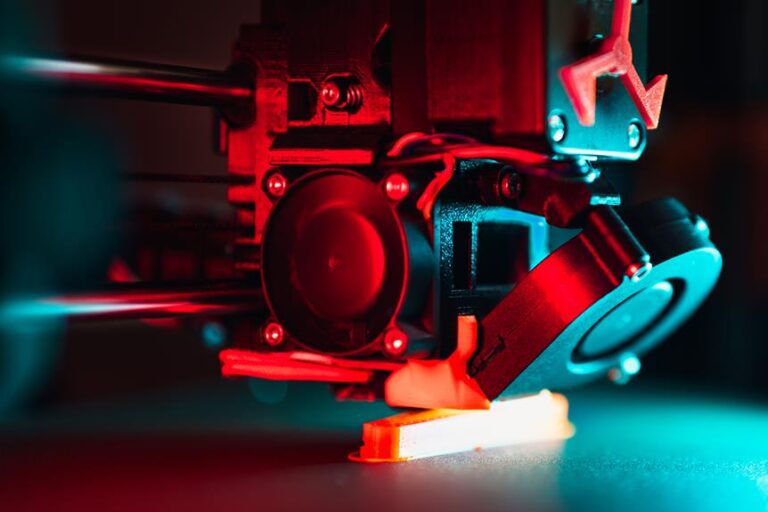

In this article, we will introduce you to the world of slicing software for 3D printers – a powerful tool that will revolutionize your printing experience.

With a focus on achieving perfect prints every time, we will delve into popular slicing software options, provide an in-depth understanding of slicing parameters, and share optimization techniques and tips for successful slicing.

Get ready for flawless 3D prints like never before.

Key Takeaways

- Slicing software converts 3D models into instructions for the printer, considering factors like layer height, print speed, and support structures.

- Popular slicing software options include Ultimaker Cura, PrusaSlicer, Simplify3D, Slic3r, and KISSlicer, each with their own unique features and capabilities.

- Understanding and optimizing slicing parameters such as layer height, print speed, infill density, and support structures is crucial for achieving perfect prints.

- Using slicing software unlocks the full potential of 3D printers, allowing users to achieve precise and accurate prints, enhance print quality and efficiency, and reduce common printing issues.

Overview of Slicing Software for 3D Printers

Undoubtedly, the overview of slicing software for 3D printers is crucial for achieving optimal printing results. Slicing software, also known as 3D printer slicers, plays a vital role in converting a 3D model into a series of instructions that the printer can understand. This software takes into account various factors such as layer height, print speed, and support structures, among others, to generate the necessary toolpaths for the printer to follow.

Slicing software allows users to fine-tune their prints by adjusting slicing settings. These settings determine the quality, speed, and accuracy of the printed object. Parameters such as layer thickness, print density, and infill percentage can be customized to meet specific requirements. Additionally, slicers enable users to control support structures, which are essential for printing complex geometries.

A good slicing software provides a user-friendly interface, allowing even beginners to navigate through the settings effortlessly. It should offer advanced features such as previewing the sliced model, simulating the printing process, and estimating the print time and material usage. Furthermore, compatibility with different file formats and support for a wide range of 3D printers are significant factors to consider when choosing slicing software.

With the right slicing software, users can unlock the full potential of their 3D printers and achieve perfect prints every time. It empowers users to explore their creativity and bring their designs to life with precision and accuracy.

Popular Slicing Software Options

There are several popular slicing software options available for 3D printers, each offering unique features and capabilities to enhance the printing experience. These software programs, also known as d printer slicers, play a crucial role in print optimization by converting 3D models into a format that the printer can understand.

To help you understand the different options, here is a comparison table highlighting some of the key features of popular slicing software:

| Slicing Software | Features |

|---|---|

| Ultimaker Cura | Open-source software with a user-friendly interface, supports a wide range of 3D printers, offers advanced settings for customization. |

| PrusaSlicer | Developed by Prusa Research, known for its reliability and ease of use, provides extensive print settings and supports multiple materials. |

| Simplify3D | Offers advanced features for expert users, allows for precise control over print settings, supports multi-material and multi-extruder printers. |

| Slic3r | Open-source software with a simple interface, supports a wide range of printers, provides customizable settings for detailed control. |

| KISSlicer | Known for its fast slicing speed, offers advanced features like automatic support generation and customizable print settings. |

Understanding the features and capabilities of different slicing software options is essential for achieving perfect prints. In the next section, we will delve into understanding slicing parameters for perfect prints, where we will explore the various settings that can be adjusted to optimize your 3D prints.

Understanding Slicing Parameters for Perfect Prints

To achieve perfect prints, it is crucial to have a deep understanding of the various slicing parameters that can be adjusted to optimize the printing process.

Slicing parameters refer to the settings that determine how a 3D model is converted into a series of layers that the 3D printer can understand. These parameters include layer height, print speed, infill density, support structures, and many others.

Layer height is an important parameter that determines the thickness of each layer in the printed object. A smaller layer height can result in smoother surfaces but longer print times.

Print speed determines how fast the printer moves while printing. Higher print speeds can reduce overall print time but may compromise the quality of the print.

Infill density determines the amount of material used to fill the interior of the object. Higher infill densities result in stronger prints but also require more material and time.

Support structures are used to provide stability for overhanging parts during printing. Optimizing the placement and density of support structures can minimize the need for post-processing.

Understanding and adjusting these slicing parameters is essential to achieve perfect prints.

In the next section, we will explore optimization techniques for flawless 3D prints, which build upon this understanding to further enhance print quality and efficiency.

Optimization Techniques for Flawless 3D Prints

One effective way to achieve flawless 3D prints is by utilizing various optimization techniques and employing a systematic approach to the printing process. These optimization techniques aim to enhance the overall quality and accuracy of the printed object, while reducing the chances of common printing issues such as warping, stringing, or layer misalignment.

One fundamental optimization technique is to properly calibrate the 3D printer. This involves adjusting the printer's settings, such as the nozzle temperature, print speed, and layer height, to ensure optimal performance. Additionally, fine-tuning the printer's bed level and nozzle height can greatly improve the adhesion between the print and the build plate, resulting in better print quality.

Another optimization technique is to optimize the model itself before slicing. This can be achieved by reducing the model's complexity, eliminating unnecessary details, and ensuring proper wall thickness. By optimizing the model, the printing process becomes more efficient and less prone to errors.

Furthermore, using the right slicing software and settings is crucial for flawless 3D prints. Slicing software allows users to convert 3D models into a series of instructions that the printer can understand. By carefully configuring the slicing parameters such as infill density, support structures, and layer orientation, users can achieve optimal print quality.

In the next section, we will explore some tips and tricks for successful slicing, which will further enhance the printing process and ensure perfect prints every time.

Tips and Tricks for Successful Slicing

Five essential tips and tricks can greatly improve the slicing process for 3D printers, ensuring successful and flawless prints every time. Slicing, the process of converting a 3D model into a set of instructions for the printer, plays a crucial role in determining the quality and accuracy of the final print.

By following these tips, users can achieve optimal results and fully unlock the potential of their 3D printers:

- Choose the right slicing software: Not all slicing software is created equal. Research and select a reliable and feature-rich software that suits your needs.

- Calibrate your printer: Properly calibrating your printer is essential for accurate prints. Ensure that the bed is leveled and the extruder is properly calibrated before starting the slicing process.

- Optimize slicing parameters: Experiment with different slicing parameters such as layer height, infill density, and print speed to find the optimal settings for your specific model and desired outcome.

- Check for errors: Before sending the sliced file to the printer, carefully inspect the preview of the sliced model for any anomalies or errors that may affect the print quality.

- Consider support structures: For complex or overhanging designs, enable support structures in the slicing software to ensure successful printing and avoid sagging or misprints.

Frequently Asked Questions

Can I Use Any Type of Slicing Software for My 3D Printer?

Yes, there are various types of slicing software available for 3D printers. However, it is important to choose a software that is compatible with your specific printer model to ensure optimal performance and achieve perfect prints every time.

How Do I Choose the Right Slicing Software for My Specific 3D Printer?

To choose the right slicing software for your specific 3D printer, consider factors such as compatibility, features, user interface, and community support. Research and compare different software options to ensure optimal performance and reliable results.

Can Slicing Software Affect the Quality of My 3D Prints?

Yes, slicing software can significantly impact the quality of 3D prints. By optimizing parameters such as layer height, infill density, and support structures, the software ensures precise and accurate prints, leading to superior results.

Is There a Difference in Slicing Software for Beginners Versus Advanced Users?

Yes, there is a difference in slicing software for beginners versus advanced users. Advanced users require more features and customization options, while beginners need simpler interfaces and automated settings to achieve good print quality.

Can Slicing Software Help With Reducing Print Time and Material Usage?

Slicing software plays a crucial role in optimizing 3D printing processes. It can significantly reduce print time and material usage by efficiently generating toolpaths and optimizing layer thickness, infill density, and support structures.

Conclusion

In conclusion, mastering slicing software for 3D printers is essential for achieving perfect prints every time.

By understanding the various slicing parameters and utilizing optimization techniques, users can ensure flawless results.

Additionally, implementing tips and tricks can further enhance the slicing process and increase the chances of success.

With this knowledge and technical precision, users can confidently create high-quality 3D prints that meet their exact specifications.