Resin 3D Printers for Jewelry Making: Creating Exquisite Designs

Unlock the limitless potential of your jewelry designs with resin 3D printers.

Delve into a world where creativity knows no bounds, as these printers bring to life exquisite pieces that captivate and inspire.

From intricate details to flawless finishes, resin printing offers unmatched precision and versatility.

Immerse yourself in the art of jewelry making, where every design becomes a masterpiece.

Join us on this liberating journey, where resin 3D printers empower you to create jewelry that is truly extraordinary.

Key Takeaways

- Resin-based printers produce high-resolution prints with exceptional detail.

- Resin offers unique color possibilities, allowing for vibrant and eye-catching designs.

- Resin 3D printed jewelry can be as durable and wearable as metal jewelry when properly cured and finished.

- Industry-leading resin 3D printers are essential for capturing intricate details and producing smooth surfaces.

The Advantages of Resin 3D Printing for Jewelry Making

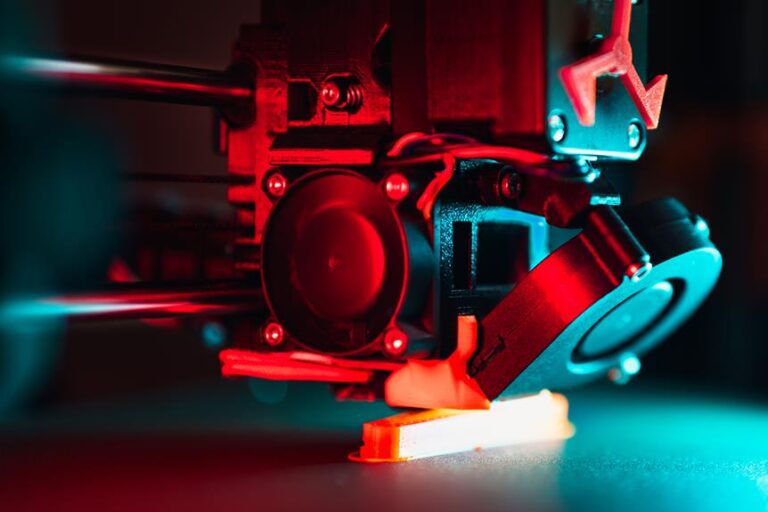

Resin 3D printing offers numerous advantages for jewelry making, consistently enabling designers to create intricate and detailed pieces. When it comes to selecting the right 3D printer for jewelry making, there are several options available, including resin-based printers such as SLA (Stereolithography) and DLP (Digital Light Processing) printers, as well as FDM (Fused Deposition Modeling) printers.

Resin-based printers are highly regarded in the jewelry making industry due to their ability to produce high-resolution prints with exceptional detail. SLA printers use a laser to solidify liquid resin, layer by layer, resulting in smooth and precise prints. DLP printers, on the other hand, use a digital projector to cure the resin, offering faster print speeds without compromising on quality.

Compared to FDM printers, resin-based printers excel in delivering intricate designs with fine details. The layer height of resin-based printers can go as low as 25 microns, allowing for the creation of delicate and complex jewelry pieces that would be challenging to achieve with FDM printers.

In the next section, we will explore the material options available for stunning jewelry designs, showcasing the versatility of resin 3D printing in creating unique and captivating pieces.

Exploring Material Options for Stunning Jewelry Designs

When it comes to material options for stunning jewelry designs, there are two main contenders: metal and resin.

While metal has long been the traditional choice for jewelry making due to its durability and timeless appeal, resin offers a unique advantage in terms of color possibilities.

Resin allows for the creation of vibrant and eye-catching designs that may not be achievable with metal alone.

Additionally, resin jewelry can be just as durable and wearable as its metal counterparts when properly cured and finished.

Metal Vs. Resin

The choice between metal and resin materials plays a crucial role in determining the overall quality and aesthetic appeal of stunning jewelry designs. Each material offers unique characteristics that can enhance the beauty and durability of the final piece.

Consider the following factors when deciding between metal and resin for your jewelry creations:

- Durability: Metal is known for its strength and longevity, making it an ideal choice for jewelry that will withstand daily wear and tear.

- Versatility: Resin allows for intricate and delicate designs that may be difficult to achieve with metal. It offers more flexibility in terms of shape and size.

- Cost: Metal jewelry tends to be more expensive due to the higher material and production costs, while resin jewelry can be more budget-friendly without sacrificing quality.

By understanding the pros and cons of each material, you can make an informed decision that aligns with your artistic vision and budget.

With the material choice in mind, let's explore the unique color possibilities that resin offers.

Unique Color Possibilities

With a wide range of material options available, jewelry designers can explore unique color possibilities to create stunning and vibrant designs. Resin 3D printers offer a plethora of choices, allowing designers to experiment with various colors and effects.

From bold and vibrant hues to subtle and delicate tones, the possibilities are endless. Imagine a necklace adorned with a deep sapphire blue pendant, or earrings featuring a shimmering emerald green. The freedom to choose from an array of colors enables designers to create jewelry that truly reflects their artistic vision.

Whether it's a statement piece or a delicate accessory, the vibrant colors achieved through resin 3D printing can add an extra dimension to any design.

In the following section, we will delve into the durability and wearability of resin 3D printed jewelry.

Durability and Wearability

For jewelry designers, the durability and wearability of resin 3D printed jewelry are crucial factors to consider when exploring material options for creating stunning jewelry designs. The choice of material can greatly impact the longevity and functionality of the final piece.

Fortunately, resin 3D printers offer a range of material options that can meet the demands of even the most discerning jewelry enthusiasts. Some of the popular material choices include:

- Castable Resin: This material is specifically designed for creating molds for metal casting. It allows designers to create intricate and delicate designs with high precision, while also ensuring durability and wearability.

- Flexible Resin: Ideal for creating bracelets, rings, and other jewelry pieces that require flexibility, this material offers a balance between durability and comfort. It allows for intricate details and can withstand everyday wear without losing its shape.

- Transparent Resin: Perfect for creating stunning gem-like designs, this material offers a crystal-clear finish that enhances the brilliance of any jewelry piece. It is durable, scratch-resistant, and can withstand the test of time.

Top Industry-Leading Resin 3D Printers for Jewelry

When it comes to selecting a resin 3D printer for jewelry making, there are several key points to consider.

Firstly, high-resolution print quality is essential to capture the intricate details and delicate designs of jewelry pieces.

Additionally, a wide range of materials is crucial to ensure compatibility with different types of jewelry, from elegant gold rings to vibrant resin earrings.

Lastly, speed and efficiency are important factors to consider, as jewelry makers often have tight deadlines and need a printer that can produce high-quality prints quickly and consistently.

High-Resolution Print Quality

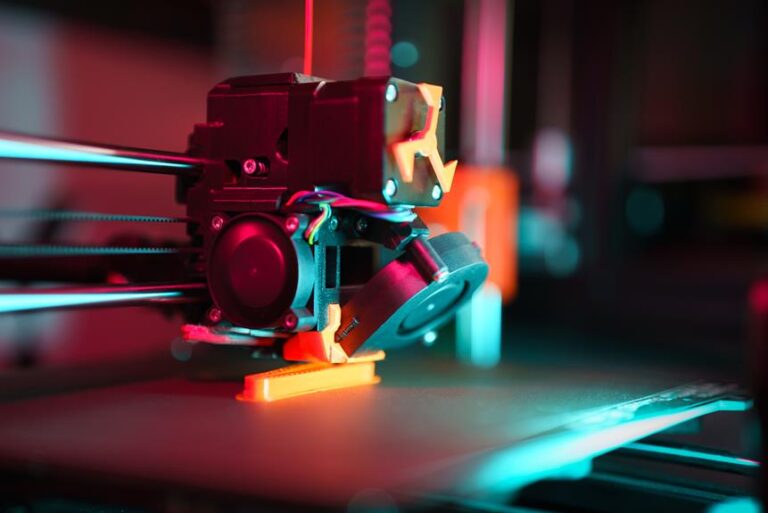

Although there are various factors to consider when choosing a resin 3D printer for jewelry making, high-resolution print quality remains a top priority for industry-leading models. With advancements in technology, these printers can produce exquisite designs with intricate details and smooth surfaces.

Here are three reasons why high-resolution print quality is crucial for jewelry making:

- Precise detailing: High-resolution printers can accurately reproduce intricate patterns and delicate features, ensuring that every tiny element of the design is captured flawlessly.

- Smooth surface finish: The top industry-leading printers deliver exceptional surface quality, minimizing the need for post-processing and reducing the time and effort required to achieve a polished and refined jewelry piece.

- Improved aesthetics: The high-resolution prints showcase the intricate details and textures of the jewelry design, enhancing its overall visual appeal and making it stand out as a truly exquisite piece of art.

For jewelry makers who strive for perfection and liberation in their craft, investing in a resin 3D printer with high-resolution print quality is essential to create stunning and captivating jewelry designs.

Wide Range of Materials

With an extensive selection of materials available, top industry-leading resin 3D printers for jewelry offer jewelry makers a wide range of options to bring their creative visions to life. These printers allow artisans to experiment with various resins, each offering unique characteristics that enhance the final product.

From clear resins that mimic the appearance of glass to opaque resins that resemble precious gemstones, the possibilities are endless. Furthermore, these printers enable the use of translucent resins, allowing light to pass through the jewelry, creating stunning visual effects.

Additionally, specialized resins with metallic or glitter particles can be used to add a touch of glamour and sparkle to the designs. With such a wide range of materials at their disposal, jewelry makers can truly push the boundaries of creativity and produce exquisite, one-of-a-kind pieces that captivate and delight.

Speed and Efficiency

Achieving high-speed and efficient production, top industry-leading resin 3D printers for jewelry streamline the manufacturing process while maintaining exceptional quality. These advanced machines offer numerous benefits that revolutionize the jewelry-making industry:

- Rapid Prototyping: Resin 3D printers allow jewelry designers to quickly create prototypes of their designs, enabling them to iterate and refine their ideas at a faster pace.

- High Precision: These printers offer incredible accuracy, ensuring intricate details and complex geometries are faithfully reproduced in the final product.

- Time Savings: The speed of resin 3D printing technology significantly reduces the production time for jewelry pieces. This allows designers to fulfill orders more quickly, meeting customer demands in a timely manner.

Through the combination of speed, precision, and time savings, top industry-leading resin 3D printers empower jewelry makers to bring their exquisite designs to life efficiently and effectively.

Liberated from the constraints of traditional manufacturing processes, designers can now explore new creative possibilities and deliver exceptional jewelry pieces to their customers.

Mastering the Art of Designing Exquisite Jewelry With Resin Printing

To truly excel in the craft of designing exquisite jewelry with resin printing, it is essential to hone one's skills and become proficient in the intricacies of the process. Resin 3D printing offers a world of possibilities for jewelry designers, allowing them to create intricate and delicate designs that were previously unimaginable. However, mastering this art requires a deep understanding of the materials and techniques involved.

First and foremost, it is crucial to have a thorough knowledge of the different types of resins available. Each resin has its own unique properties, such as transparency, flexibility, or hardness, which can greatly impact the final result. Familiarizing oneself with the characteristics of various resins is essential for choosing the right material for each design.

In addition, attention to detail is paramount when designing jewelry with resin printing. The level of precision and accuracy required is unparalleled, as even the slightest imperfection can detract from the overall beauty of the piece. This involves not only mastering the software used for designing the jewelry but also understanding the limitations and capabilities of the 3D printer itself.

Furthermore, creativity is a crucial aspect of designing exquisite jewelry with resin printing. Pushing the boundaries of traditional jewelry design and exploring new possibilities is what sets exceptional designers apart. Embracing innovation and thinking outside the box can result in truly unique and breathtaking pieces.

Techniques and Tips for Achieving High-Quality Jewelry Prints

Utilizing precise calibration and meticulous post-processing are key techniques for producing high-quality jewelry prints with resin 3D printers. Achieving exquisite designs requires attention to detail and a thorough understanding of the printing process.

Here are some techniques and tips to help you create stunning jewelry pieces with resin 3D printing:

- Optimal Calibration: Calibrating your 3D printer is crucial for achieving precise and accurate prints. Ensure that the build plate is leveled correctly, and the resin vat is properly aligned. Fine-tune the printer's settings, such as exposure time and layer height, to achieve the desired level of detail.

- Support Structures: Designing effective support structures is essential to ensure the stability of intricate jewelry designs during the printing process. Strategically place supports to minimize post-processing efforts and prevent warping or distortion of delicate features.

- Post-Processing Mastery: After the print is complete, post-processing plays a vital role in achieving a high-quality finish. Rinse the printed object in isopropyl alcohol to remove uncured resin. Use a UV curing chamber or natural sunlight to fully cure the print, ensuring its strength and durability.

Pushing the Boundaries of Creativity With Resin 3D Printing

By exploring the limitless possibilities of resin 3D printing, jewelry designers can push the boundaries of creativity and unlock new levels of innovation in their craft. Resin 3D printing technology offers a wide range of benefits that allow designers to create intricate and unique pieces that were once only possible through traditional methods. With the ability to print complex geometries, intricate details, and delicate structures, designers can now bring their wildest imaginations to life.

One of the key advantages of resin 3D printing is its ability to produce highly detailed and precise designs. The high resolution and accuracy of resin 3D printers enable designers to create intricate patterns, textures, and shapes that were previously impossible to achieve. This opens up a whole new world of possibilities for jewelry designers, allowing them to experiment with unconventional designs and push the boundaries of what is considered traditional jewelry.

To further illustrate the potential of resin 3D printing in jewelry making, let's take a look at the following table:

| Resin 3D Printing Advantages | Emotions Evoked |

|---|---|

| Unlimited Design Possibilities | Excitement and curiosity |

| Precise and Intricate Details | Awe and amazement |

| Faster Production Time | Impatience and eagerness |

| Customization and Personalization | Freedom and individuality |

As you can see, resin 3D printing offers a range of advantages that not only enhance the creative process but also evoke a sense of liberation and excitement. With these capabilities at their fingertips, jewelry designers can break free from the confines of traditional techniques and create truly unique and innovative pieces that captivate and inspire.

Showcasing the Beauty and Versatility of Resin-Printed Jewelry

The beauty and versatility of resin-printed jewelry are evident in their intricate designs and wide range of applications. Resin 3D printers have revolutionized the jewelry-making industry by allowing designers to create stunning pieces that were once thought impossible.

Here are some ways resin-printed jewelry showcases its beauty and versatility:

- Intricate details: Resin 3D printers can produce intricate and delicate designs that are simply breathtaking. From delicate filigree patterns to intricate textures, resin-printed jewelry captures even the tiniest details with precision.

- Customization: Resin printing offers endless possibilities for customization. Designers can easily modify and personalize their creations, ensuring that each piece of jewelry is unique and tailored to the individual wearer's preferences.

- Material variety: Resin 3D printers can work with a wide range of materials, including various types of resins and even composite materials like metal-infused resins. This versatility allows designers to experiment with different textures, colors, and finishes, resulting in jewelry that is truly one-of-a-kind.

Resin-printed jewelry not only showcases its beauty and versatility but also empowers designers to push the boundaries of creativity. With the ability to bring intricate designs to life and customize every aspect of their creations, resin 3D printing has opened up a world of possibilities for jewelry makers. Liberating designers from traditional constraints, resin-printed jewelry is a true testament to the power of technology and artistic expression.

Frequently Asked Questions

What Are the Safety Precautions to Take When Working With Resin 3D Printers for Jewelry Making?

When working with resin 3D printers for jewelry making, it is crucial to prioritize safety. This includes wearing protective gear such as gloves and goggles, ensuring proper ventilation, and handling and disposing of resin materials responsibly.

Can Resin 3D Printers Print Multiple Colors in a Single Print?

Yes, resin 3D printers have the capability to print multiple colors in a single print. This feature allows for the creation of intricate and visually stunning designs, enhancing the overall quality and appeal of jewelry pieces.

Are Resin 3D Printers Suitable for Printing Delicate and Intricate Jewelry Designs?

Resin 3D printers are exceptionally suitable for printing delicate and intricate jewelry designs. Their high precision and ability to capture intricate details allow for the creation of exquisite and unique pieces.

How Long Does It Take to Print a Jewelry Piece Using a Resin 3D Printer?

The printing time for a jewelry piece using a resin 3D printer can vary depending on factors such as complexity, size, and resolution. However, with advancements in technology, it is now possible to create intricate designs in a relatively short period of time.

Can Resin 3D Printers Be Used to Print Jewelry With Gemstones or Other Embellishments?

Yes, resin 3D printers can be used to print jewelry with gemstones or other embellishments. The precise and intricate nature of resin printing allows for the creation of exquisite designs that incorporate various elements and details, enhancing the overall aesthetic appeal of the jewelry piece.

Conclusion

Resin 3D printing has revolutionized the world of jewelry making, allowing designers to create exquisite and intricate designs that were once unimaginable.

With a wide range of material options and industry-leading printers, the possibilities for creating stunning jewelry are endless.

By mastering the art of designing with resin printing and employing techniques for achieving high-quality prints, jewelry makers can push the boundaries of creativity and showcase the beauty and versatility of resin-printed jewelry.

The future of jewelry making has never been more exciting.