Enhancing Product Development With 3D Scanning and Printing Services

In the realm of product development, the pursuit of innovation and efficiency has become paramount.

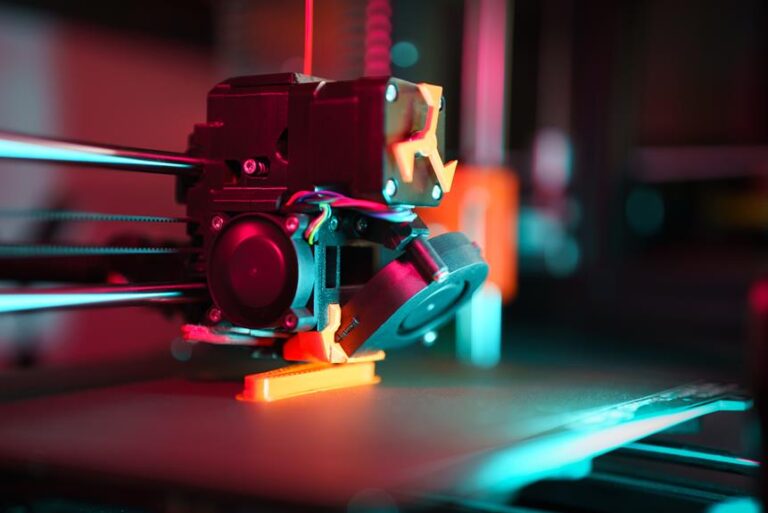

Enter the dynamic duo of 3D scanning and printing services, a transformative technology that has revolutionized the way products are conceptualized, prototyped, and manufactured.

This article explores the myriad benefits and possibilities that arise from harnessing the power of 3D scanning and printing, offering a glimpse into a future where creativity knows no bounds and productivity knows no limits.

Key Takeaways

- 3D scanning and printing services accurately capture intricate details and measurements of physical objects, allowing for the creation of high-quality virtual models and rapid prototyping.

- These services reduce time and cost in the development process, enabling faster design iterations and modifications, as well as saving money compared to traditional manufacturing methods.

- Reverse engineering with 3D scanning allows for cost-effective design improvements, streamlines manufacturing processes, and leads to better products and increased customer satisfaction.

- 3D scanning and printing services enhance quality control and inspection processes by providing accurate measurements, enabling non-destructive testing, and improving the ability to detect and resolve potential issues.

The Power of 3D Scanning in Product Development

One of the key advantages of 3D scanning in product development is its ability to accurately capture intricate details and measurements of physical objects. This technology has revolutionized the way products are designed and manufactured, offering a range of benefits to businesses and consumers alike.

3D scanning allows for precise and detailed digital representations of real-world objects. By capturing the geometry and surface texture of an object, designers can create high-quality virtual models that can be used for various purposes. This level of accuracy is crucial in product development, as it ensures that every aspect of the design is captured and accounted for.

In addition to capturing intricate details, 3D scanning also enables rapid prototyping services. Once the digital model is created, it can be used to produce physical prototypes using 3D printing technology. This allows designers to quickly iterate and test their designs, reducing both time and cost in the development process.

Furthermore, 3D scanning and printing services offer customizability and flexibility. With the ability to scan and reproduce physical objects, businesses can provide personalized products to consumers. This opens up a world of possibilities for customization, giving customers the freedom to create unique products that cater to their specific needs and preferences.

Leveraging 3D Printing for Faster Prototyping

3D printing offers businesses the opportunity to accelerate the prototyping process by providing a faster and more efficient way to produce physical models. By leveraging this technology, companies can save time and money while also gaining a competitive edge in the market.

One of the main advantages of 3D printing for prototyping is its speed. Traditional manufacturing methods often involve lengthy processes, such as mold-making or CNC machining, which can take weeks or even months. In contrast, 3D printing allows for rapid production of prototypes, reducing the time it takes to go from design to physical model.

Furthermore, 3D printing enables iterative design and quick modifications. With traditional prototyping methods, making changes to a design can be costly and time-consuming. However, with 3D printing, modifications can be easily implemented by simply adjusting the digital design file and reprinting the prototype.

To highlight the benefits of leveraging 3D printing for faster prototyping, here is a table showcasing a comparison between traditional prototyping methods and 3D printing:

| Traditional Prototyping Methods | 3D Printing |

|---|---|

| Lengthy production time | Rapid production |

| Expensive tooling costs | Lower costs |

| Limited design flexibility | Iterative design |

| Complex manufacturing process | Simplified process |

Exploring the Benefits of Reverse Engineering With 3D Scanning

Reverse engineering using 3D scanning offers several benefits for product development.

Firstly, it allows for cost-effective design improvements by capturing the physical geometry of existing products and replicating or modifying them digitally.

Secondly, it streamlines manufacturing processes by providing accurate measurements and specifications, enabling manufacturers to produce parts more efficiently.

Lastly, reverse engineering with 3D scanning accelerates product development by reducing the time required for design iterations and prototyping, ultimately leading to faster time-to-market for new products.

Cost-Effective Design Improvements

The implementation of cost-effective design improvements through the utilization of 3D scanning and printing services can significantly enhance product development processes.

By employing 3D scanning technology, designers can capture precise and accurate measurements of existing products or prototypes. This data can then be used to create digital models, which can be modified and optimized using computer-aided design (CAD) software. With the ability to quickly iterate and make adjustments, designers can explore different design options and identify potential improvements without the need for costly physical prototypes.

This not only reduces the time and expense associated with traditional design processes but also allows for more creative freedom and innovation. By leveraging the benefits of reverse engineering and 3D scanning, companies can achieve cost-effective design improvements that ultimately lead to better products and increased customer satisfaction.

This seamless transition from design to manufacturing aids in streamlining the overall product development and manufacturing processes.

Streamlining Manufacturing Processes

By harnessing the advantages of reverse engineering and utilizing 3D scanning technology, companies can optimize manufacturing processes and achieve greater efficiency.

Reverse engineering involves the process of replicating or improving an existing product by analyzing its structure and functionality.

With 3D scanning, manufacturers can capture accurate and detailed measurements of physical objects, creating digital models that can be used for analysis and modification.

This allows companies to identify areas for improvement and make necessary changes to streamline the manufacturing process.

By eliminating the need for manual measurements and reducing human errors, 3D scanning enhances precision and saves time.

Additionally, the ability to quickly create prototypes using 3D printing further accelerates the manufacturing process, enabling companies to bring products to market faster.

Ultimately, reverse engineering with 3D scanning empowers manufacturers to optimize their processes, reduce costs, and deliver high-quality products to consumers efficiently.

Accelerating Product Development

Utilizing 3D scanning technology in combination with reverse engineering significantly accelerates product development by providing precise measurements and detailed digital models for analysis and modification.

This powerful combination allows engineers and designers to quickly capture the physical properties of an existing product and convert it into a digital format. By scanning an object and creating a 3D model, manufacturers can easily identify areas for improvement, make design modifications, and enhance the overall product development process.

The ability to reverse engineer components also enables companies to reproduce and replace obsolete parts, saving time and resources. Additionally, 3D scanning and reverse engineering facilitate rapid prototyping, allowing for quicker iterations and faster product iterations.

Streamlining Product Design With 3D Printing Services

To efficiently optimize the product design process, businesses can leverage the benefits of 3D printing services.

3D printing, also known as additive manufacturing, has revolutionized the way products are designed and prototyped. By using 3D printing technology, businesses can streamline their product design process and significantly reduce both time and cost.

One major advantage of 3D printing in product design is the ability to quickly create physical prototypes. Traditional manufacturing methods often require expensive tooling and molds, which can be time-consuming to produce. With 3D printing, designers can simply input their digital designs into the printer and have a physical prototype within hours or days. This allows for rapid iteration and refinement of the design, ultimately leading to a better end product.

Furthermore, 3D printing enables designers to create complex and intricate geometries that would be difficult or even impossible to achieve with traditional manufacturing methods. This opens up new possibilities for innovative and unique product designs that can captivate consumers and differentiate businesses from their competitors.

By streamlining the product design process with 3D printing services, businesses can enhance their ability to bring new products to market faster and more efficiently. This not only saves time and money but also allows for more iterative design cycles, resulting in better products that meet customer demands.

In the next section, we will explore how businesses can further enhance their product development process by utilizing 3D scanning technology to improve quality control.

Enhancing Quality Control Through 3D Scanning Technology

3D scanning technology offers businesses the opportunity to improve quality control throughout the product development process. By utilizing this advanced technology, companies can enhance their ability to detect and resolve potential issues before they become major problems.

Here are four ways in which 3D scanning technology can enhance quality control:

- Accurate measurements: 3D scanners provide highly accurate measurements of physical objects, allowing businesses to compare them against design specifications. This enables them to identify any discrepancies or defects and make necessary adjustments to ensure product quality.

- Non-destructive testing: With 3D scanning, companies can perform non-destructive testing on prototypes and finished products. This means that they can thoroughly inspect the items without causing any damage, allowing for a more efficient and cost-effective quality control process.

- Defect detection: 3D scanning technology can identify even the smallest defects or imperfections in a product. By scanning the entire surface of an object, businesses can detect flaws that may not be visible to the naked eye, ensuring that only high-quality products are released to the market.

- Documentation and traceability: 3D scanning provides a detailed digital record of each product, allowing for better documentation and traceability. This not only helps in identifying any quality control issues but also enables businesses to track and monitor the manufacturing process, ensuring consistency and compliance with quality standards.

Accelerating Innovation With 3D Printing in Product Development

How can the integration of 3D printing technology accelerate innovation in the product development process?

3D printing has revolutionized the way products are designed, prototyped, and manufactured. This technology allows for the creation of complex and intricate designs that were previously unimaginable. By using 3D printing in product development, companies can accelerate the innovation process in several ways.

Firstly, 3D printing enables faster iteration and prototyping. Traditional manufacturing methods often involve lengthy and expensive processes to create prototypes. With 3D printing, designers can quickly and cost-effectively produce multiple iterations of a product, allowing for rapid testing and refinement.

Additionally, 3D printing facilitates the exploration of new design possibilities. The freedom of design that 3D printing offers allows for the creation of products with unique and innovative features. This opens up opportunities for designers to think outside the box and come up with groundbreaking solutions.

Moreover, 3D printing reduces the time and cost of tooling. Traditional manufacturing methods require the creation of molds or tooling, which can be time-consuming and expensive. With 3D printing, products can be directly manufactured without the need for tooling, saving both time and money.

Maximizing Efficiency in Manufacturing With 3D Scanning

By implementing 3D scanning technology, manufacturers can significantly improve efficiency and streamline their manufacturing processes. Here are four ways in which 3D scanning can maximize efficiency in manufacturing:

- Quality Control: 3D scanning allows manufacturers to accurately measure and inspect parts, ensuring that they meet the required specifications. This reduces the need for manual inspections and minimizes the risk of errors or defects in the final products.

- Rapid Prototyping: With 3D scanning, manufacturers can quickly create digital models of physical objects and generate accurate prototypes. This speeds up the product development cycle, allowing for faster iterations and reducing time-to-market.

- Reverse Engineering: 3D scanning enables manufacturers to reverse engineer existing products or components, capturing their geometry and dimensions. This facilitates the replication or modification of parts, saving time and resources in the manufacturing process.

- Tooling and Mold Making: 3D scanning can be used to create digital models of tooling and molds, which are essential in manufacturing processes. These digital models can be used to optimize and refine the design, reducing the need for costly and time-consuming physical iterations.

Unlocking New Possibilities With 3D Printing in Product Development

When it comes to product development, 3D printing offers a range of benefits that can unlock new possibilities.

One of these benefits is reducing time-to-market by enabling faster prototyping and iteration. With 3D printing, companies can quickly produce and test multiple design iterations, allowing them to identify and address any issues or improvements before moving into full-scale production.

Additionally, 3D printing is a cost-effective solution for prototyping, as it eliminates the need for expensive molds or tooling. By leveraging 3D printing technology, companies can save time and money while bringing innovative products to market more efficiently.

Reducing Time-to-Market

Implementing 3D printing in the product development process accelerates time-to-market and opens up new avenues for innovation. With traditional manufacturing methods, it can take weeks or even months to produce prototypes and iterate on designs. However, 3D printing allows for rapid prototyping, reducing the time required to bring a product to market.

Here are four ways in which 3D printing reduces time-to-market:

- Faster prototyping: 3D printers can quickly produce functional prototypes, enabling designers to test and iterate on their designs more efficiently.

- Streamlined production: 3D printing eliminates the need for tooling and molds, reducing production lead times and allowing for on-demand manufacturing.

- Customization and personalization: 3D printing enables the creation of customized products, tailored to individual customer needs, without the need for extensive retooling or setup.

- Agile manufacturing: 3D printing allows for rapid changes in design and production, enabling businesses to respond quickly to market demands and customer feedback.

Cost-effective Prototyping

Cost-effective prototyping can revolutionize the product development process by utilizing 3D printing technology and enabling companies to iterate on designs quickly and efficiently. By using 3D printing for prototyping, companies can save time and money compared to traditional methods. With 3D printing, designers can quickly create physical prototypes of their products, allowing for faster design iterations and improvements. This means that companies can test and refine their designs more efficiently, leading to better end products. Additionally, 3D printing enables the production of complex geometries and intricate details that may be difficult or costly to achieve with traditional manufacturing methods. The table below highlights some of the cost-saving benefits of using 3D printing for prototyping:

| Cost Savings Benefits of 3D Printing for Prototyping |

|---|

| Reduced material waste |

| Faster design iterations |

| Lower tooling costs |

| Reduced labor costs |

| Improved product quality |

Frequently Asked Questions

How Much Does 3D Scanning Technology Cost?

The cost of 3D scanning technology varies depending on factors such as the complexity of the object being scanned, the type of scanner used, and the desired level of detail. It is important to consult with a reputable provider for accurate pricing information.

Can 3D Printing Be Used for Mass Production?

Yes, 3D printing can be used for mass production. It allows for the rapid production of customized products, reduces time and costs compared to traditional manufacturing methods, and enables flexibility in design iterations.

What Materials Can Be Used With 3D Printing Services?

Various materials can be used with 3D printing services, including plastics, metals, ceramics, and composites. The choice of material depends on factors such as desired properties, cost, and application requirements.

Is Reverse Engineering With 3D Scanning an Accurate Process?

Reverse engineering with 3D scanning is an accurate process that allows for the creation of precise digital models of existing objects. This technology captures the physical dimensions and geometry of an object, enabling accurate replication or modification in product development.

Can 3D Scanning Technology Be Integrated With Existing Manufacturing Processes?

Yes, 3D scanning technology can be integrated with existing manufacturing processes to enhance product development. It allows for accurate digitization of physical objects, which can be used for design modifications, quality control, and rapid prototyping.

Conclusion

In conclusion, the integration of 3D scanning and printing services in product development has revolutionized the industry by enhancing efficiency, accelerating innovation, and unlocking new possibilities.

This technology has allowed for faster prototyping, improved quality control, and streamlined product design processes.

By leveraging the benefits of reverse engineering, manufacturers are able to create more advanced and precise products.

Overall, 3D scanning and printing services have significantly improved the product development process, leading to enhanced outcomes and customer satisfaction.