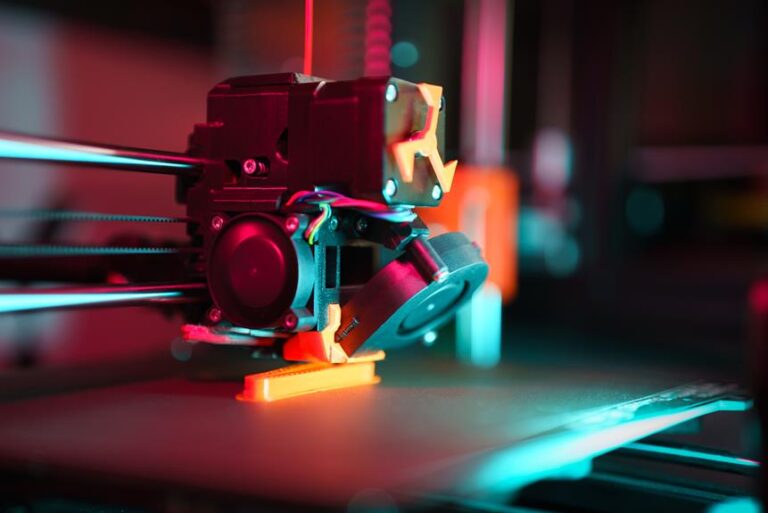

TPU Filament: Enable Flexible and Elastic 3D Prints

Prepare to revolutionize your 3D printing experience with TPU filament – the key to unlocking the potential of flexible and elastic prints.

In this article, we will delve into the basics of TPU filament, exploring its unique properties and the numerous benefits it offers in the realm of 3D printing.

Discover invaluable tips for successful TPU printing, guidance on selecting the right filament, and troubleshooting common issues.

Join us as we explore the limitless possibilities of TPU filament in the world of flexible 3D printing.

Key Takeaways

- TPU filament is highly elastic and flexible, allowing for the creation of prints that can bend and flex without breaking.

- TPU filament has excellent layer adhesion and printability, minimizing warping or distortion.

- TPU filament has good chemical resistance and high UV resistance, making it suitable for harsh environments and outdoor applications.

- TPU filament is ideal for a wide range of applications, including prototyping, functional parts, wearable devices, and industries such as fashion, sports, and healthcare.

The Basics of TPU Filament

Exploring the properties and characteristics of TPU filament is essential for understanding its applications in creating flexible and elastic 3D prints. TPU, or thermoplastic polyurethane, is a type of filament that offers unique advantages in the field of 3D printing.

One of the key properties of TPU filament is its flexibility. Unlike other filaments, such as PLA or ABS, TPU filament is highly elastic, allowing for the creation of prints that can be bent, stretched, and compressed without breaking. This makes TPU filament ideal for applications that require parts with high resilience and durability, such as shoe soles, phone cases, and prosthetics.

In addition to its flexibility, TPU filament also exhibits excellent layer adhesion and printability. It has a low shrinkage rate, which means that prints made with TPU filament have minimal warping or distortion. This ensures that the final product retains its intended shape and dimensions.

Furthermore, TPU filament has good chemical resistance, making it suitable for use in environments where exposure to chemicals or oils is a concern. It also has a high level of UV resistance, making it suitable for outdoor applications where prolonged exposure to sunlight is expected.

Understanding the Unique Properties of TPU

TPU filament possesses a combination of physical properties, such as high elasticity and chemical resistance, that make it stand out from other 3D printing materials. TPU, which stands for thermoplastic polyurethane, is a versatile material that can be used in various applications, including manufacturing prototypes, creating flexible parts, and producing durable products.

One of the key properties of TPU is its high elasticity. It has the ability to stretch and bend without losing its shape or breaking. This makes it ideal for producing objects that require flexibility, such as phone cases, shoe soles, and wearable devices. Additionally, TPU has excellent chemical resistance, which means it can withstand exposure to various chemicals without deteriorating or deforming.

To further understand the unique properties of TPU, let's take a look at the following table:

| Property | Description |

|---|---|

| Elasticity | TPU has high elasticity, allowing it to stretch and bend without breaking. |

| Chemical Resistance | TPU exhibits excellent resistance to various chemicals, making it suitable for applications in harsh environments. |

| Flexibility | TPU is highly flexible, enabling the production of objects that require bending or folding. |

Benefits of Using TPU Filament in 3D Printing

TPU filament offers several benefits in 3D printing. It provides enhanced print flexibility, improved elasticity properties, and increased design possibilities.

With TPU filament, users can create prints that are able to bend and flex without breaking. This makes it ideal for applications such as prototyping, functional parts, and wearable devices.

Additionally, TPU filament has high elasticity. This allows for the creation of intricate and complex designs, enabling users to push the boundaries of what is possible in 3D printing.

Enhanced Print Flexibility

With its ability to seamlessly adhere to intricate designs, TPU filament revolutionizes the flexibility of 3D prints.

TPU, short for Thermoplastic Polyurethane, is a type of filament that offers exceptional elasticity and durability. When used in 3D printing, it allows for the creation of objects that can bend, stretch, and flex without breaking.

This enhanced print flexibility opens up a world of possibilities in various industries, including fashion, sports, and healthcare. TPU filament's flexibility is especially beneficial for creating wearable items like clothing, shoes, and prosthetics, as it provides a comfortable fit and allows for movement.

Additionally, TPU filament's ability to withstand impact and resist abrasion makes it suitable for applications that require durable and long-lasting parts.

Improved Elasticity Properties

By providing enhanced elasticity and flexibility, TPU filament offers numerous benefits for 3D printing applications. TPU, or thermoplastic polyurethane, is a popular choice for creating objects that require high levels of elasticity.

Some of the key advantages of using TPU filament in 3D printing include:

- Improved impact resistance: TPU can withstand sudden impacts and deformation without breaking, making it ideal for applications that require durability.

- Increased flexibility: TPU filament allows for the creation of 3D prints that can be bent, twisted, and stretched without losing their shape or integrity.

- Excellent layer adhesion: TPU has excellent layer adhesion properties, ensuring that the printed object remains intact and does not delaminate.

- Versatile applications: TPU filament can be used for a wide range of applications, including wearable technology, prosthetics, shoe soles, and protective cases.

With these improved elasticity properties, TPU filament opens up a world of possibilities for designers and engineers to explore in terms of increased design possibilities.

Increased Design Possibilities

The utilization of TPU filament in 3D printing allows for the exploration of a wide range of design possibilities, enabling designers and engineers to push the boundaries of creativity and innovation. TPU filament offers several benefits that contribute to increased design possibilities. Firstly, its flexibility and elasticity make it ideal for creating intricate and complex geometries that would be difficult to achieve with traditional materials. Additionally, TPU filament's high impact resistance and durability allow for the creation of functional prototypes and end-use parts that can withstand heavy usage. Furthermore, TPU filament's ability to adhere well to various surfaces and its compatibility with different printing techniques provide designers with the freedom to experiment with different textures and finishes. Overall, the use of TPU filament in 3D printing opens up new avenues for design and empowers designers to create truly unique and innovative products.

| Design Possibilities Enabled by TPU Filament | Benefits |

|---|---|

| Creation of intricate and complex geometries | Enables the production of highly detailed and unique designs |

| High impact resistance and durability | Allows for the creation of functional and long-lasting parts |

| Compatibility with different printing techniques | Provides flexibility in choosing the most suitable printing method |

| Excellent adhesion to various surfaces | Enables the creation of textured and multi-material designs |

| Freedom to experiment with different finishes | Offers versatility in achieving desired aesthetics |

Tips for Successful TPU Printing

To achieve high-quality TPU prints, it is essential to carefully adjust the printer settings. TPU, or thermoplastic polyurethane, is a flexible filament that requires specific settings to ensure successful printing.

Here are some tips to help you achieve the best results:

- Extruder Temperature: TPU has a lower melting point compared to other filaments, so it is crucial to set the extruder temperature correctly. Start with a lower temperature, around 220-230°C, and adjust accordingly based on the printing quality and filament manufacturer's recommendations.

- Print Speed: TPU requires slower print speeds due to its flexible nature. Increase the print time to allow the filament to properly bond and avoid any potential issues like stringing or warping.

- Bed Adhesion: TPU has a tendency to warp, so ensuring proper bed adhesion is crucial. Use a heated bed with temperatures around 60-70°C and consider using a build plate adhesive like hairspray or a specialized TPU adhesive.

- Retraction Settings: TPU is prone to stringing, so adjusting the retraction settings is important. Decrease the retraction distance to reduce the chances of stringing while maintaining good print quality.

By following these tips, you can optimize your TPU printing experience and achieve high-quality, flexible prints.

Now, let's move on to the next section and discuss how to choose the right TPU filament for your project.

Choosing the Right TPU Filament for Your Project

When it comes to choosing the right TPU filament for your project, there are several important points to consider.

First, it is crucial to compare the material properties of different TPU filaments to ensure they meet the requirements of your application.

Additionally, optimizing print settings such as nozzle temperature and print speed can greatly affect the quality and performance of your 3D prints.

Lastly, selecting a filament that is specifically designed for your project's needs, whether it be for flexibility, durability, or other specific characteristics, is essential for achieving the desired results.

Material Properties Comparison

One of the key factors to consider when choosing a TPU filament for your project is its material properties. To help you make an informed decision, here are four important aspects to compare:

- Shore Hardness: This measures the material's resistance to indentation. A higher value indicates a harder filament, suitable for applications requiring more rigidity.

- Elongation at Break: This indicates the maximum stretch a filament can endure before breaking. Higher values mean greater flexibility and elasticity.

- Tensile Strength: This measures the filament's ability to withstand pulling or stretching forces. A higher value indicates greater strength and durability.

- Printability: Consider the filament's compatibility with your 3D printer and its ease of use. Look for features like good layer adhesion, minimal warping, and reliable extrusion.

Print Settings Optimization

For optimal results, it is essential to consider print settings optimization when selecting the appropriate TPU filament for your project.

Print settings optimization refers to the adjustment of various parameters such as nozzle temperature, print speed, layer height, and infill density to achieve the best print quality and performance with TPU filament.

When it comes to TPU, it is crucial to find the right balance between print speed and temperature. Higher temperatures ensure better layer adhesion and flexibility, but excessive heat can lead to stringing and over-softening of the filament. Additionally, slower print speeds allow for better control of the filament flow and reduce the likelihood of print failures.

By fine-tuning these settings, you can achieve high-quality, flexible, and elastic 3D prints with TPU filament.

Now let's delve into the next section, which focuses on selecting the appropriate TPU filament for your specific project.

Project-Specific Filament Selection

To ensure optimal results, it is imperative to carefully select the appropriate TPU filament for your project by considering its specific requirements and characteristics. Choosing the right TPU filament can greatly impact the success of your 3D prints.

Here are four important factors to consider when selecting TPU filament:

- Shore Hardness: TPU filaments come in various hardness levels, measured on the Shore A scale. Softer filaments with lower Shore Hardness values (e.g., 70A) offer higher flexibility, while harder filaments (e.g., 95A) provide better durability.

- Tensile Strength: Consider the required strength of your 3D prints. TPU filaments with higher tensile strength are suitable for applications that require structural integrity and resistance to stretching or tearing.

- Elasticity: Some TPU filaments exhibit excellent elasticity and can stretch significantly without deforming or breaking. This property is crucial for applications that require flexibility and resilience.

- Chemical Resistance: Evaluate the filament's resistance to chemicals, oils, and solvents, depending on the intended use of your prints. Certain TPU filaments offer enhanced chemical resistance, making them suitable for specific applications such as industrial parts or medical devices.

Recommended Print Settings for TPU Filament

The optimal print settings for TPU filament ensure successful production of flexible and elastic 3D prints. When working with TPU, it is important to consider the filament diameter, print temperature, print speed, and bed adhesion.

TPU filaments typically have a diameter of 1.75mm or 2.85mm, so it is crucial to match the filament diameter with the corresponding printer settings to ensure accurate extrusion.

In terms of print temperature, TPU filaments generally require a lower temperature compared to other materials. A recommended starting point for the print temperature is around 210-230°C. However, it is essential to adjust the temperature based on the specific characteristics of the TPU filament being used.

It is also advised to print at a slower speed to prevent any stringing or oozing issues. A print speed of around 20-40 mm/s is a good starting point.

Additionally, proper bed adhesion is vital for successful TPU prints. Using a heated bed with a temperature of around 60-70°C and applying a suitable adhesive, such as a build plate adhesive or blue painter's tape, can greatly improve bed adhesion.

In the next section, we will discuss troubleshooting common TPU printing issues and how to overcome them to ensure high-quality prints.

Troubleshooting Common TPU Printing Issues

When encountering common TPU printing issues, users can employ troubleshooting techniques to overcome them and achieve optimal print quality. Here are some common TPU printing issues and their respective solutions:

- Stringing: To prevent stringing, users can adjust the retraction settings in their 3D printer software. Increasing the retraction distance and speed can help reduce the amount of filament being pulled and prevent stringing between printed parts.

- Warping: Warping occurs when the corners of a printed object start to lift or curl up. To prevent warping, users can ensure that the printer bed is properly leveled and that the first layer adheres well to the bed. Additionally, using a heated bed and an enclosure can help maintain a consistent temperature, reducing the chances of warping.

- Under-extrusion: Under-extrusion happens when the printer fails to push out enough filament, resulting in weak and incomplete prints. This issue can be resolved by adjusting the extrusion multiplier or increasing the flow rate in the printer settings.

- Clogging: TPU filament is more prone to clogging due to its flexibility and elasticity. To prevent clogging, users can clean the nozzle regularly and make sure the filament is properly loaded and feeding correctly. Increasing the printing temperature slightly can also help prevent clogs.

TPU Applications in Flexible 3D Printing

TPU (Thermoplastic Polyurethane) filament offers a range of benefits for flexible 3D printing applications. Its inherent flexibility and elasticity make it ideal for creating objects that require bendability and stretchability.

TPU filament is commonly used in industries such as footwear, automotive, and healthcare, where the ability to produce durable and functional prototypes or end-use parts is crucial.

TPU Benefits for Flexibility

One of the main advantages of TPU filament in flexible 3D printing is its ability to produce highly elastic and stretchable objects. TPU, or thermoplastic polyurethane, is a versatile material that offers several benefits for flexibility in 3D printing.

- Excellent elasticity: TPU filaments can stretch and bend without breaking, making them ideal for creating objects that require flexibility, such as wearable devices or shoe soles.

- Impact resistance: TPU has good impact resistance, allowing printed objects to withstand external forces without deforming or breaking.

- Shore hardness options: TPU filaments are available in different shore hardness levels, ranging from soft and rubber-like to harder and more rigid, providing flexibility to choose the right material for specific applications.

- Chemical resistance: TPU exhibits resistance to various chemicals, ensuring that the printed objects remain durable and functional in different environments.

Wide Range of Applications

With its exceptional flexibility and elasticity, TPU filament finds applications in various industries and sectors where the ability to create flexible 3D prints is essential. From healthcare to fashion, TPU 3D printing has revolutionized the way products are designed and manufactured. The table below highlights some of the wide-ranging applications of TPU filament in flexible 3D printing:

| Industry | Applications |

|---|---|

| Healthcare | Customized prosthetics, medical devices |

| Fashion | Flexible clothing, shoes, accessories |

| Automotive | Interior components, gaskets |

| Sports | Protective gear, footwear |

| Robotics | Grippers, soft touch sensors |

In healthcare, TPU filament enables the production of customized prosthetics and medical devices that offer better fit and comfort for patients. In the fashion industry, designers can create flexible clothing, shoes, and accessories that provide enhanced comfort and functionality. Automotive manufacturers use TPU filament to produce interior components and gaskets that require flexibility. In the sports industry, TPU filament is used to create protective gear and footwear that offer improved performance and comfort. Finally, in robotics, TPU filament enables the production of grippers and soft touch sensors that can interact with delicate objects without causing damage. These applications demonstrate the versatility and potential of TPU filament in various industries.

TPU Vs. Other Flexible Filaments: a Comparison

When comparing TPU filament to other flexible filaments, it is important to consider their unique properties and applications. TPU, or thermoplastic polyurethane, is a popular choice for flexible 3D printing due to its excellent elasticity and durability.

Here are some key points to consider when comparing TPU to other flexible filaments:

- Flexibility: TPU is known for its high flexibility, allowing it to be easily bent, stretched, and compressed. This makes it ideal for applications that require parts with a lot of movement or need to withstand repeated stress.

- Shore Hardness: TPU filaments come in different shore hardness levels, ranging from soft and flexible to more rigid. This versatility allows for a wide range of applications, from soft and squishy toys to more rigid and durable functional parts.

- Chemical Resistance: TPU exhibits good resistance to oils, greases, and many chemicals, making it suitable for applications in industries such as automotive, healthcare, and manufacturing.

- Printability: TPU can be challenging to print due to its flexibility and low melting temperature. However, with the right printer settings and techniques, it can produce high-quality prints with good layer adhesion and minimal warping.

Considering these properties, TPU filament stands out as a versatile and reliable choice for flexible 3D printing. Its unique characteristics make it an excellent option for a wide range of applications.

Now, let's explore how TPU filament has become a game-changer in 3D printing technology.

TPU Filament: A Game-Changer in 3D Printing Technology

TPU filament has revolutionized the field of 3D printing technology, offering unprecedented possibilities for creating flexible and elastic prints. This thermoplastic polyurethane material is known for its excellent mechanical properties, making it a game-changer in the industry.

TPU filament is highly flexible, allowing for the creation of objects that can bend, stretch, and compress without breaking. It is also resistant to abrasion, tear, and impact, making it ideal for applications that require durability and toughness. Additionally, TPU filament has good chemical resistance, making it suitable for use in various environments.

The following table illustrates the key advantages of TPU filament in 3D printing:

| Advantages of TPU Filament |

|---|

| Excellent flexibility |

| High durability |

| Chemical resistance |

TPU filament is compatible with most FDM/FFF 3D printers and can be used to create a wide range of products, including footwear, clothing, phone cases, gaskets, and prosthetics. Its ability to produce flexible and elastic prints has opened up new possibilities in industries such as fashion, sports, and healthcare.

Frequently Asked Questions

Can TPU Filament Be Used With Any 3D Printer?

Yes, TPU filament can be used with most 3D printers that have a heated bed and an extruder capable of reaching the required temperature for TPU printing, which is typically around 220-240°C.

What Is the Shelf Life of TPU Filament?

The shelf life of TPU filament can vary depending on storage conditions and manufacturer recommendations. It is important to store TPU filament in a cool, dry place away from moisture and direct sunlight to ensure its longevity and optimal printing performance.

Can TPU Filament Be Recycled?

TPU filament can be recycled, making it an environmentally friendly choice for 3D printing. Its flexibility and elasticity allow for the creation of intricate and functional designs, expanding the possibilities in various industries.

How Does TPU Filament Compare to Other Flexible Filaments in Terms of Strength?

When comparing the strength of TPU filament to other flexible filaments, it exhibits superior resilience and durability. Its robustness allows for the creation of 3D prints that can withstand high levels of stress and strain.

Can TPU Filament Be Used for Functional Prototypes or Only for Decorative Prints?

TPU filament can be used for both functional prototypes and decorative prints. Its flexible and elastic properties make it suitable for creating functional parts that require flexibility, such as hinges or gaskets, while also offering aesthetic options for decorative prints.

Conclusion

In conclusion, TPU filament offers a game-changing solution for flexible and elastic 3D printing. Its unique properties allow for the creation of durable and functional objects that can withstand bending and stretching.

By understanding the basics of TPU filament and following the tips for successful printing, users can harness the benefits of this material in various applications.

With its increasing popularity, it is worth noting that TPU filament sales are projected to reach $102.3 million by 2023, indicating its significant impact on the 3D printing industry.