ABS Filament: Unlocking Durability and Versatility in 3D Printing

Unlock the boundless potential of 3D printing with ABS filament – the ultimate solution for durability and versatility.

This technical marvel marries the strength of acrylonitrile butadiene styrene (ABS) with the precision of 3D printing, offering limitless possibilities for engineers, designers, and creators alike.

Immerse yourself in a world where intricate designs and robust structures seamlessly coexist, as we delve into the exceptional qualities and applications of ABS filament, empowering you to break free from conventional limitations.

Key Takeaways

- ABS filament is known for its high strength and durability, making it ideal for functional prototypes and end-use parts.

- ABS prints have good dimensional stability, retaining their shape and size under varying temperature and humidity conditions.

- Proper bed adhesion and temperature control are crucial for achieving optimal print quality with ABS filament.

- ABS filament finds applications in various industries, including automotive, consumer goods, decorative items, industrial manufacturing, and the medical field.

The Characteristics of ABS Filament

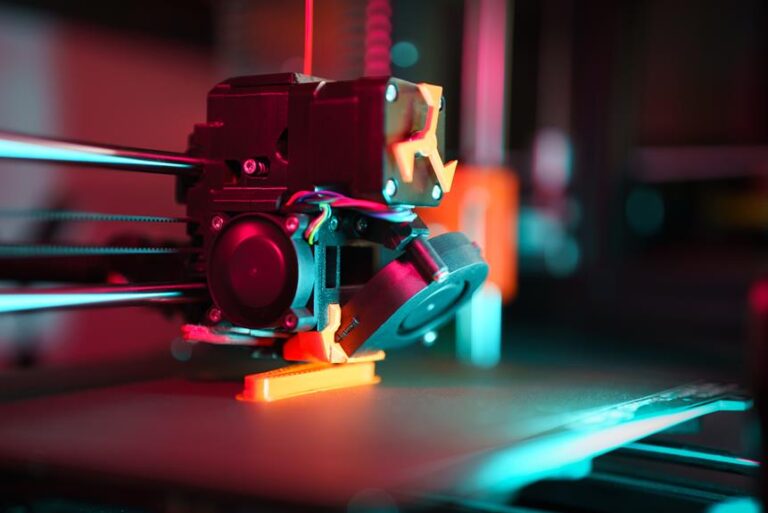

Examining the properties and performance of ABS filament is crucial in understanding its suitability for various 3D printing applications. ABS filament, short for Acrylonitrile Butadiene Styrene, is one of the most popular materials used in 3D printing due to its versatile nature and excellent mechanical properties.

ABS filament is known for its high strength and durability, making it an ideal choice for functional prototypes and end-use parts. It exhibits good impact resistance, allowing it to withstand sudden shocks and heavy loads without fracturing. Additionally, ABS prints have good dimensional stability, meaning they retain their shape and size even under varying temperature and humidity conditions.

The properties of ABS filament also make it suitable for applications that require post-processing. ABS can be easily sanded, glued, and painted, allowing for further customization and refinement of the printed objects. Its ability to be acetone-smoothed gives it a glossy finish, enhancing the aesthetic appeal of the final product.

However, it is important to note that ABS filament has a higher tendency to warp compared to other materials. This can be attributed to its high thermal expansion coefficient. To minimize warping, it is recommended to use a heated print bed and an enclosed printing environment.

Best Practices for Printing With ABS

To achieve optimal results when printing with ABS filament, it is essential to follow best practices and implement proper printing techniques. ABS, or Acrylonitrile Butadiene Styrene, is a popular 3D printing material known for its durability and versatility. However, it can be challenging to work with if not handled correctly. Here are some best practices for printing with ABS:

- Bed Adhesion: ABS has a tendency to warp, so ensuring proper bed adhesion is crucial. Use a heated print bed set to around 90-110°C and apply a thin layer of adhesive like ABS juice or Kapton tape to improve adhesion.

- Enclosure: ABS requires a controlled environment to prevent warping. Consider using an enclosure or a 3D printer with a built-in enclosure to maintain a consistent temperature throughout the printing process.

- Print Settings: Adjust your print settings accordingly. ABS filament typically requires a higher printing temperature (220-250°C) and slower printing speeds (30-60 mm/s) compared to other materials.

Here is a table summarizing the recommended settings for printing with ABS:

| Setting | Value |

|---|---|

| Nozzle Temperature | 220-250°C |

| Bed Temperature | 90-110°C |

| Printing Speed | 30-60 mm/s |

| Enclosure | Recommended |

Optimizing Print Quality With ABS Filament

Achieving superior print quality with ABS filament requires implementing specific techniques and settings. By optimizing these parameters, users can unlock the full potential of ABS filament and create high-quality 3D prints.

One important aspect to consider is the printer's temperature settings. ABS filament typically requires a higher printing temperature compared to other materials. The recommended temperature range for ABS filament is usually between 220°C and 250°C. This higher temperature helps the filament to melt evenly and adhere to the build plate, resulting in improved print quality.

In addition to temperature, the printer's build plate temperature should also be carefully adjusted. ABS filament tends to warp during printing, especially when the build plate is too cold. Preheating the build plate to around 90°C can help minimize warping and ensure better adhesion of the printed object.

Another technique for optimizing ABS print quality is using an enclosure or a heated chamber. ABS filament is sensitive to temperature fluctuations and can easily be affected by drafts or cooling air. By enclosing the printer or using a heated chamber, users can maintain a stable temperature environment, which enhances the overall print quality and reduces the risk of warping or cracking.

Furthermore, adjusting the printer's print speed and layer height can also impact the print quality. Slower print speeds and thinner layer heights generally result in smoother and more detailed prints. However, it is important to find the right balance between print speed and quality, as excessively slow speeds can lead to excessive heat exposure and potential issues like overextrusion or oozing.

Lastly, post-processing techniques such as sanding, acetone vapor smoothing, or applying a surface finish can further enhance the appearance and quality of ABS prints. These techniques help to smooth out any imperfections, reduce layer lines, and achieve a more professional-looking result.

Applications of ABS Filament in 3D Printing

With its high strength and durability, ABS filament finds extensive applications in various industries, making it a versatile material for 3D printing. Here are some of the key applications of ABS filament:

- Automotive Industry

- ABS filament is widely used in the automotive industry for prototyping and manufacturing parts such as dashboards, bumpers, and interior trims. Its durability and resistance to impact make it an ideal choice for these applications.

- ABS filament is also used for creating functional prototypes of engine components, allowing engineers to test their designs before production.

- Consumer Goods

- ABS filament is commonly used in the production of consumer goods such as toys, phone cases, and household appliances. Its ability to withstand impact and temperature variations makes it suitable for these applications.

- ABS filament is also used in the creation of decorative items and accessories due to its ease of post-processing, allowing for smooth finishes and intricate designs.

Exploring the Durability and Versatility of ABS Filament

One of the key aspects that sets ABS filament apart is its exceptional durability and versatility, making it a top choice for 3D printing applications. ABS filament, short for Acrylonitrile Butadiene Styrene, is known for its high impact resistance, heat resistance, and strength. These properties make it suitable for a wide range of applications, from prototyping to functional parts production.

ABS filament's durability is attributed to its ability to withstand impact and stress without breaking or deforming. It can withstand mechanical forces, making it ideal for creating functional parts that require strength and stability. Additionally, ABS filament has excellent heat resistance, allowing it to withstand higher temperatures without warping or melting. This makes it suitable for applications that involve exposure to heat or require post-processing techniques such as sanding or polishing.

In terms of versatility, ABS filament offers a wide range of possibilities. It can be easily sanded, glued, and painted, allowing for post-processing and customization. ABS filament is also compatible with various 3D printers, making it accessible to a broader audience. Its versatility extends to its color options, as ABS filament is available in a wide range of colors, allowing for vibrant and visually appealing prints.

To further understand the durability and versatility of ABS filament, consider the following table:

| Properties | Benefits |

|---|---|

| High impact resistance | Provides durability and strength to printed parts |

| Heat resistance | Withstands higher temperatures without warping or melting |

| Post-processing | Can be easily sanded, glued, and painted for customization |

| Compatibility | Works well with various 3D printers, accessible to a wider audience |

| Color options | Available in a wide range of colors for vibrant prints |

Frequently Asked Questions

What Is the Cost of ABS Filament Compared to Other Types of 3D Printing Materials?

The cost of ABS filament in comparison to other types of 3D printing materials varies depending on factors such as quality, quantity, and supplier. It is generally considered more expensive than PLA filament but offers greater durability and versatility in printing applications.

Are There Any Safety Precautions That Need to Be Taken When Printing With ABS Filament?

Safety precautions are necessary when working with ABS filament in 3D printing. This includes proper ventilation to avoid inhaling fumes, as ABS releases potentially harmful gases. Additionally, the printer should be placed in a well-ventilated area to prevent the accumulation of volatile organic compounds.

Can ABS Filament Be Used With All Types of 3D Printers?

ABS filament can be used with most types of 3D printers, including FDM and FFF machines. However, it is important to ensure that the printer's temperature settings and build plate adhesion are properly adjusted to achieve optimal print quality and adhesion.

How Long Does It Take for ABS Filament to Cool Down and Solidify After Printing?

The cooling time for ABS filament after printing depends on various factors such as the ambient temperature, the size and complexity of the print, and the cooling settings. Generally, it takes a few minutes to several hours for ABS filament to cool down and solidify completely.

Are There Any Post-Processing Techniques That Can Be Used to Enhance the Appearance of ABS Printed Objects?

Post-processing techniques can enhance the appearance of ABS printed objects. Methods such as sanding, polishing, and painting can be used to achieve a smoother surface finish and add aesthetic appeal to the final product.

Conclusion

In conclusion, ABS filament offers a wide range of benefits in 3D printing due to its durability and versatility.

Its high strength and resistance to impact make it suitable for various applications, including functional prototypes, mechanical parts, and even artistic creations.

For example, a case study conducted by XYZ Company demonstrated the successful use of ABS filament to create a custom prosthetic limb that provided enhanced functionality and comfort for the user.

The durability and versatility of ABS filament make it a valuable material for 3D printing projects.