Pioneering progress in production, 3D printing presents profound possibilities.

This article delves into the dynamic domain of 3D printing, exploring its evolution, mechanism, and materials.

We will also examine the transformative trends in the future of 3D printing, its impact on sustainability, job market, and economy, as well as legal and safety considerations.

Join us as we journey through this technological revolution, transforming ideas into tangible objects with the power of 3D printing.

Key Takeaways

- 3D printers use various technologies such as FDM, SLA, and SLS to create objects layer by layer.

- Different types of 3D printers, including FDM, resin, and metal printers, have their own advantages and disadvantages depending on the intended application.

- Materials used in 3D printing include thermoplastic filaments, resin, and metal powder, each offering different properties and characteristics.

- 3D printing offers benefits such as enhanced productivity, improved customization, and cost-effectiveness for small-scale production and prototyping.

Understanding 3D Printing Technology

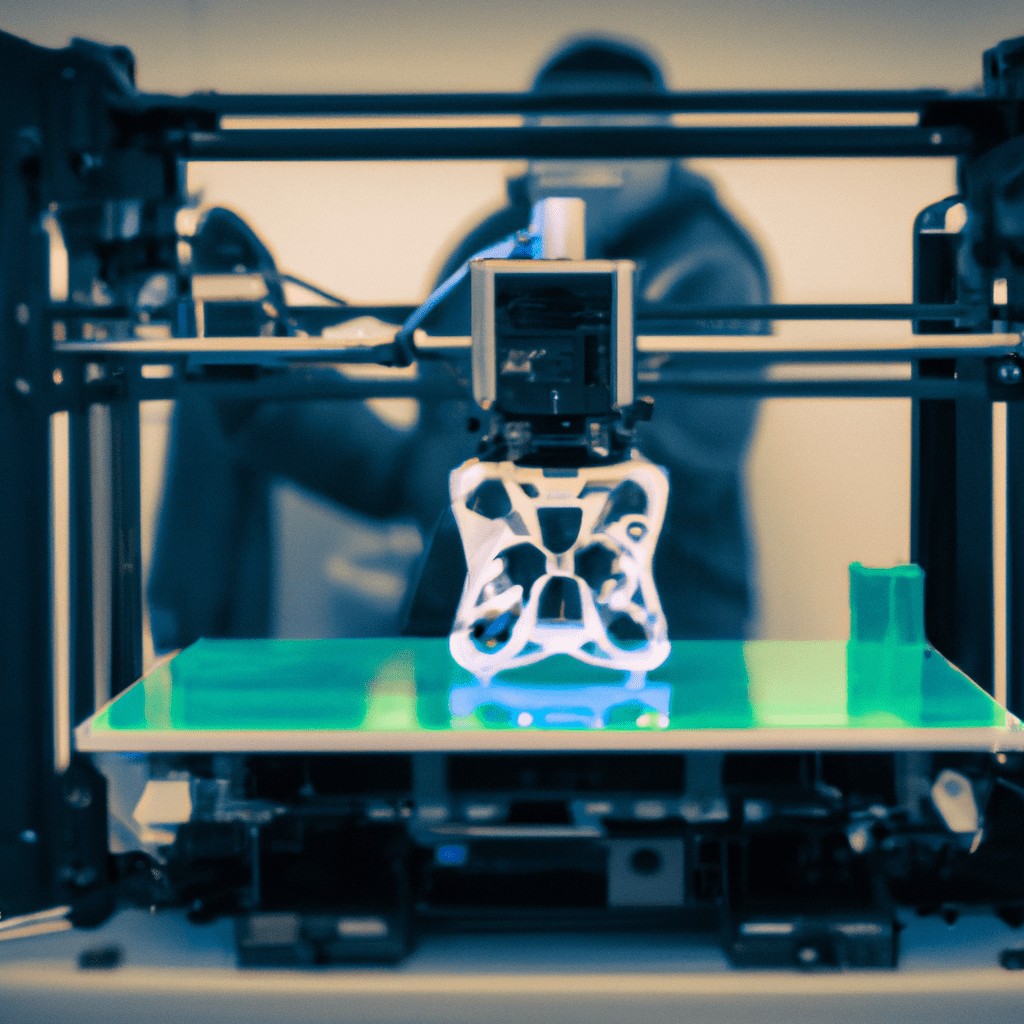

Delving into the realm of 3D printing technology, we must first comprehend its basic principles and mechanics. A 3D printer is a marvel of modern ingenuity, taking digital blueprints and transforming them into tangible objects. This process is made possible through FDM 3D printing, where the 3D printing machine systematically layers d printer filament, a type of 3D printing material, to construct the desired object.

The cost of a 3D printer can vary greatly depending on its capabilities. For example, an SLA 3D printer, which uses light to harden liquid resin, can be more expensive than a typical FDM printer. However, the superior resolution and finish of resin printers often justify the higher price tag.

It is also possible to construct a DIY 3D printer, which can be a cost-effective and educational venture. This requires a solid understanding of the technology, as well as a keen eye for detail to ensure precision and functionality.

The History of 3D Printers

Building on our understanding of 3D printing technology, it is imperative to explore the history of 3D printers, a journey that underscores the evolution of this remarkable manufacturing revolution. The inception of 3D printing can be traced back to 1984 when Charles Hull invented stereolithography, a printing process that allows the creation of 3D models using digital data.

| Year | Development | Notable Printers |

|---|---|---|

| 1984 | Invention of stereolithography | – |

| 2008 | Introduction of RepRap project, a self-replicating printer | Prusa d printer |

| 2012 | Emergence of affordable printers | Creality Ender 3 |

| 2014 | Commercial use of metal 3D printing | – |

| 2019 | 3D printed house | – |

The RepRap project in 2008 notably led to the creation of the Prusa d printer. By 2012, the industry had evolved to introduce affordable 3D printers such as the Creality Ender 3, making this technology accessible to the masses. The best d printer is subjective and depends on the user’s needs. As the d printer price continues to decrease, more applications like the d printed house become possible. The Creality d printer and Flashforge d printer are notable contributors to the current d printing service industry.

How 3D Printers Work

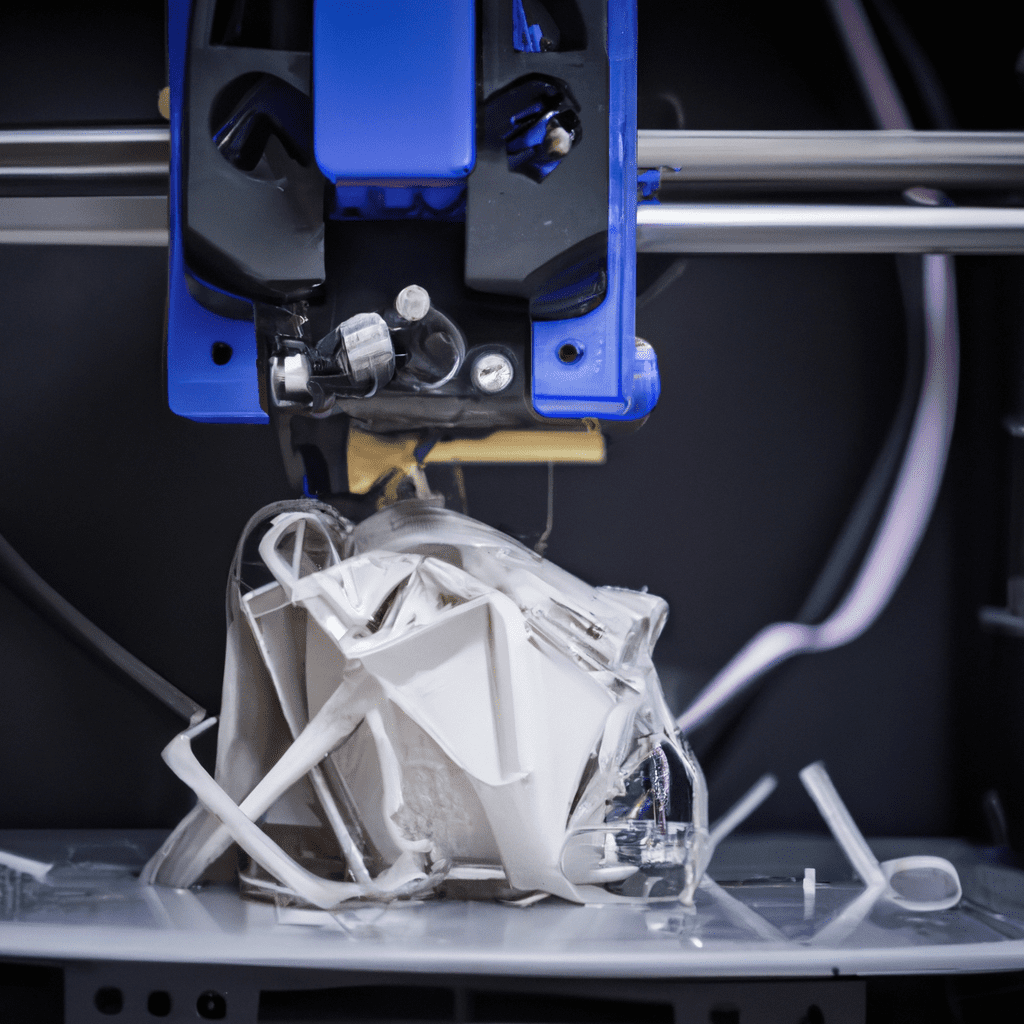

Transitioning from the historical evolution of 3D printing, the intricacy of its functionality becomes a captivating subject of exploration. Let’s dive into how 3D printers work.

At the core of a 3D printing machine is the concept of additive manufacturing, where objects are created layer by layer, a process guided by a 3D slicer. The slicer converts a digital 3D model into a series of thin layers, creating a comprehensive path for the 3D printer to follow.

There are several types of 3D printers. The FDM printer, or fused deposition modeling printer, is the most common. It heats a thermoplastic filament, extruding it layer by layer to form the object. The SLA printer, or stereolithography apparatus printer, uses a light source to cure liquid resin into hardened plastic. The SLS printer, or selective laser sintering printer, uses a laser to sinter powdered material.

From creating intricate 3D printer projects at home to large-scale production in a 3D printing store, the applications are endless. With a 3D printer near me, anyone can witness this technology in action.

As we see the increase in 3D printers for sale, understanding their operation becomes vital. Let’s move on to explore the different types of 3D printers in detail.

Different Types of 3D Printers

Frequently in the realm of 3D printing, we encounter several distinct types of printers, each boasting unique techniques and applications. For instance, the Ultimaker Cura and Creality Ender Pro are Fused Deposition Modeling (FDM) printers, known for their use of PLA and ABS filaments. In contrast, the Anycubic Photon and Ender 3D printer, fall under the resin 3D printer category, utilizing UV light to cure liquid resin.

| Printer Type | Example | Material Used |

|---|---|---|

| FDM | Ultimaker Cura, Creality Ender Pro | PLA and ABS Filament |

| Resin | Anycubic Photon, Ender D Printer | Liquid Resin |

| Metal | Prusa i3 MK | Metal Powder |

| Cheap | Ender D Printer | Various |

Another type is the Prusa i3 MK, a metal 3D printer that uses metal powder, providing robust and durable results. Lastly, for those on a budget, cheap 3D printers like the Ender D Printer are available, offering a variety of material compatibility. It is essential to understand these differences when selecting a 3D printer, as each has its pros and cons depending on the intended application.

Materials Used in 3D Printing

Understanding the various materials utilized in 3D printing is integral to maximizing the technology’s potential and achieving desired results. The most commonly used material is the 3D filament, which comes in different types, each with unique properties that suit different applications.

One such type is the Thermoplastic Polyurethane (TPU filament), notable for its durability and flexibility. It is often used in printing objects that need to withstand significant wear and tear. The choice of slicer software, such as Prusa Slicer or Creality Slicer, plays a crucial role in determining the end product’s quality when using this type of filament.

In addition to TPU, resin is also a popular material in 3D printing, especially when high-resolution and intricate details are required. The best resin 3D printer can produce parts with smooth surfaces and fine features.

Furthermore, slicer software like Cura Ultimaker is extensively used, given its advanced features that enhance the 3D printing process. Using Cura for 3D printing allows for efficient manipulation of the printing parameters.

Lastly, platforms like Thingiverse 3D and MakerBot Thingiverse offer a vast array of 3D models, further expanding the possibilities of what can be created with these materials.

Guide to Choosing a 3D Printer

In light of the material variety’s importance in 3D printing, a user’s choice of the printer becomes equally critical to ensure optimal results. This guide to choosing a 3D printer will help users understand the factors to consider when deciding on the best device for their needs.

First, consider the size of the objects you plan to print. For larger items, a large 3D printer like the Creality Ender 5 Pro is a suitable choice. If you’re just starting out in 3D printing, the best 3D printer for beginners is one with an intuitive interface and easy setup. Anycubic 3D printer and Prusa printers are renowned for their user-friendly designs.

Next, consider your budget. The best budget 3D printer does not necessarily mean it’s of lower quality. Printers like the Flashforge Creator Pro offer excellent value for money. For those seeking professional-grade output, the Ultimaker 3D printer is a worthy investment.

If you lack space or resources for a printer at home, look for ‘3D printing near me’ online to find local services.

The Benefits of 3D Printing

Harnessing the capabilities of a well-chosen 3D printer unlocks numerous benefits, significantly transforming various aspects of production and design. They range from the Creality Ender, Prusa Mini, and Anycubic Vyper to the Ultimaker, Snapmaker, Makerbot Replicator, Anycubic Photon Mono X, and Creality CR. Each 3D printer, when paired with a reliable 3D printing service, can lead to enhanced productivity, improved customization, and cost-effectiveness.

| 3D Printer | Benefit |

|---|---|

| Creality Ender/CR | Enhanced speed |

| Prusa Mini/Vyper | Improved quality |

| Ultimaker/Snapmaker | High customizability |

By reducing the time it takes to go from design to prototype, 3D printers like the Creality Ender and CR offer a significant advantage in speed. The Prusa Mini and Anycubic Vyper are known for their superior quality output. The Ultimaker and Snapmaker stand out for their high level of customizability, allowing intricate designs to be brought to life with precision.

Moving forward, we will delve into the financial implications of utilizing 3D printing, comparing costs of traditional manufacturing versus 3D printing, to help you make an informed decision about integrating this innovative technology into your production process.

Comparing Costs: Traditional Manufacturing Vs 3D Printing

Transitioning from the benefits of 3D printing, we now shift our focus to a comprehensive comparison between the costs associated with traditional manufacturing and 3D printing. Cost efficiency is a key consideration for businesses, and it’s important to weigh the expenses related to both methods.

To make an informed decision, let’s delve into the following aspects:

-

Initial Investment:

-

Traditional manufacturing typically requires substantial upfront investment in heavy machinery and tooling.

-

In contrast, 3D printing, with models like the Prusa i MKS, Creality Ender V, AnyCubic Kobra, Artillery Sidewinder X, Elegoo Mars Pro, AnyCubic Mega S, Creality CR SE, Creality D, and Voron D printer, often requires a lower initial investment.

-

Production and Operating Costs:

-

The cost per unit in traditional manufacturing decreases with volume, making it more cost-effective for large-scale production.

-

3D printer & 3D printing service, on the other hand, provide a cost-effective solution for small-scale production and prototyping due to minimal setup costs and flexibility in design changes.

The Challenges of 3D Printing

While 3D printing offers numerous advantages, it is not without its own set of challenges that need to be addressed for efficient operation and optimal results. One of the primary difficulties in 3D printing services is the high cost of equipment.

For instance, while the Creality Ender S, Ender V, and Ender Pro offer excellent print quality, their price tags can be prohibitive for smaller businesses or independent users. Printers like the Prusa i and Prusa XL, although more affordable, have their own issues such as limited build volume and slower print speed. The Anet A and Flashforge Adventurer, on the other hand, have been noted for their inconsistent print quality.

There are also technical complications, such as the constant need for calibration, intricate software knowledge, and advanced maintenance requirements. Servicing and calibration are especially critical for the Ultimaker S to maintain its exceptional precision.

Moreover, 3D printing, despite its technological advancements, still has issues with material limitations. The range of suitable materials is narrower compared to traditional manufacturing techniques, which can limit the scope of projects.

Having addressed these challenges, our next section will delve into the many exciting and innovative applications of 3D printing.

Exploring 3D Printing Applications

Delving into the realm of 3D printing applications, we discover a myriad of innovative uses spanning across various industries. The versatility of this technology is accentuated by the diverse range of printers available, including popular models like the Ender S, Prusa MKS, Ender Plus, FLSun, Ender Max, Prusa MK, Sovol SV, Creality Halot One, CR, and Biqu B.

The applications of these printers can be broadly classified into two categories:

-

Industrial Applications

-

The Ender S and Ender Plus are frequently employed in the production of custom tools, prototypes, and end-use parts.

-

The FLSun and Ender Max excel in architectural modeling due to their superior build volume.

-

Personal Use

-

The Prusa MKS and MK are favored by hobbyists for their excellent print quality and extensive online support.

-

The Sovol SV, Creality Halot One, CR, and Biqu B are preferred for their user-friendly interfaces, making them ideal for beginners.

3D Printing in Healthcare

In the context of healthcare, 3D printing has emerged as a revolutionary tool, transforming various aspects of patient care and medical research.

The Anycubic Photon Mono, Phrozen Sonic Mini 4K, and Artillery Genius Pro are among the leading printers utilized for producing high-resolution anatomical models for surgical planning.

The Ender S Pro and Voxelab Aquila have been instrumental in creating personalized prosthetics and implants, enhancing patient outcomes significantly.

The Phrozen Sonic Mega 5K and Anycubic Photon M have been deployed in the creation of intricate medical devices, aiding in the development of novel therapeutic approaches.

Innovative printers like the Anycubic Photon Mono X 4K and Artillery Hornet further accelerate this trend, offering more precision in bio-printing and tissue engineering.

Despite the ongoing advancements, it is crucial to consider the technical limitations and ethical implications of 3D printing in healthcare.

The future promises even more specialized printers, like the Anycubic Photon Mono 4K, offering greater accuracy and consistency.

As the technology continues evolving, healthcare providers must remain adaptive and vigilant to leverage the full potential of 3D printing while ensuring patient safety and regulatory compliance.

3D Printing in Construction

Numerous construction companies are harnessing the capabilities of 3D printing to construct diverse structures, ranging from simple residential buildings to complex architectural designs, with increased efficiency and precision. The Anker D printer, for instance, is making a mark in the industry with its superior accuracy and speed, while the Elegoo Neptune and Elegoo Neptune Pro are being lauded for their impressive print volume and quality.

The construction sector is revolutionised by several remarkable 3D printers:

-

High-performance models:

-

Anycubic Kobra Max: Known for its reliability and precise output

-

Anycubic Chiron: Distinguished by its large build volume

-

Speedy and efficient models:

-

Ender V Neo: Renowned for its fast printing speed

-

Flsun Super Racer: Esteemed for its superior rapid prototyping capabilities

The Elegoo Jupiter, Ankermake M, and Artillery Genius are also contributing notably in the domain with their unique features, offering a competitive edge to construction firms.

As we delve deeper into the transformative power of 3D printing, it becomes clear that this technology will continue to play a pivotal role in the construction industry. As we transition to the subsequent section, we will discuss the impact and applications of 3D printing in the automotive industry.

3D Printing in Automotive Industry

Transitioning from construction, 3D printing is also making significant strides in the automotive industry, revolutionizing the way vehicles are designed and manufactured. Companies are employing advanced 3D printers such as Voron and Bambu Lab X, known for their high precision and ability to handle complex geometries, to create intricate car parts that were previously impossible to produce.

Moreover, the use of Elegoo Mars and Bambu Lab X Carbon printers has catalyzed the production of lightweight and robust automotive components contributing to fuel efficiency and vehicle lifespan. The AnkerMake and Prusad printers have been instrumental in rapid prototyping, reducing the time to market and enhancing product development cycles.

3D printing has also enabled the creation of customized car parts. With tools like the Snapmaker Artisan, Creality Ender Plus, and Anycubic Photon S, manufacturers can now print parts tailored to individual customer preferences.

The Bambu Lab has been particularly instrumental in this regard, leading the way in the development of 3D printed car interiors. The potential of these technologies is immense and continues to be explored. As we delve deeper into the capabilities of 3D printing, the next area of focus is its application in the world of fashion and design.

3D Printing in Fashion and Design

Harnessing the power of 3D printing technology, fashion designers and artists worldwide are redefining the boundaries of creativity, birthing an era of bespoke clothing and intricate design pieces. The use of various 3D printers, such as the Toybox 3D printer, Kingroon KPS, and Dremel D printer, allows for the creation of custom designs at an unprecedented scale and detail.

Key applications in the fashion and design industry include:

- Custom clothing and accessories:

- Bambulab uses the Photon Mono X and Tronxy X5A for creating unique and tailored items.

- Yeggi D is utilized for personalizing designs, offering a new level of customizability.

- Artistic pieces and decor:

- The FLSun Q and Ender S Plus are often used in the creation of intricate home decor items.

- BLTouch is employed for precise measurements, ensuring the highest level of detail in each piece.

The utilization of these technologies is not only reshaping the fashion and design industry but is also paving the way for a more sustainable and personalized future. The possibilities are limitless, marking an exciting time for designers and innovators alike.

How 3D Printing Services Operate

In the realm of 3D printing services, three primary steps define their operation: design creation, file conversion, and the actual printing process.

The design phase is where the idea takes shape. Advanced software, such as the Voron Trident, is used to create a 3D model. The model is then converted into a file format that the 3D printer can read, usually STL or OBJ.

This conversion process is necessary to translate the 3D design into a series of thin layers, which the printer will lay down one at a time. The printer reads the file, heats the chosen material, and extrudes it layer by layer to create the 3D object. The final result is a precise physical representation of the initial digital design.

Here’s a simple table summarizing the process:

| Steps | Description |

|------------------|-------------|

| Design Creation | Using software like Voron Trident to create a 3D model |

| File Conversion | Transforming the 3D model into a printer-friendly file |

| Printing Process | The printer reads the file and creates the object layer by layer |Understanding how 3D printing services operate can aid in maximizing their potential, from rapid prototyping to creating intricate designs.

When to Use a 3D Printing Service

Leveraging a 3D printing service becomes vital when your project requires precision, rapid prototyping, or complex designs that traditional manufacturing methods cannot efficiently produce.

Here are two scenarios where 3D printing services are crucial:

-

Rapid Prototyping:

-

Speed: 3D printing allows for quick turnaround times, streamlining the prototyping process.

-

Flexibility: It enables you to make quick design iterations without the need for expensive tooling or setup costs.

-

Complex Designs:

-

Precision: 3D printing can produce parts with complex geometries that are challenging for traditional manufacturing methods.

-

Customization: It allows for high levels of customization without significantly increasing production time or cost.

The decision to utilize a 3D printing service is not merely a question of convenience; it’s a strategic choice that can significantly impact the efficiency, cost, and success of a project. By understanding the unique advantages of this technology, businesses and individuals alike can make informed decisions about when to leverage these services.

As we transition into the next section, we will delve into what to expect from a 3D printing service, equipping you with the knowledge to effectively utilize this revolutionary technology.

What to Expect From a 3D Printing Service

With respect to utilizing a 3D printing service, one should anticipate a range of features including rapid production, high precision, and the ability to handle complex designs. These services leverage advanced technologies to convert digital models into tangible objects swiftly, which can be beneficial in rapid prototyping or manufacturing scenarios.

High precision is another key aspect to expect. 3D printing processes, such as Stereolithography (SLA), Selective Laser Sintering (SLS), or Fused Deposition Modelling (FDM), are capable of producing parts with fine details and tight tolerances. This makes them suitable for applications that require a high level of accuracy, such as aerospace or medical industries.

Furthermore, 3D printing technologies have the unique capability to fabricate complex geometries that are impossible or very difficult to create with traditional manufacturing methods. This allows for more design freedom and can lead to innovative products and solutions.

Lastly, expect professional consultation and support. A good 3D printing service will provide expert advice on material selection, print settings, and post-processing techniques to ensure the best outcome.

Armed with this knowledge, the next section will guide you in selecting a reliable 3D printing service.

Selecting a Reliable 3D Printing Service

Although there are numerous 3D printing services available in the market, selecting a reliable one requires careful consideration of several key factors. These factors, if overlooked, can lead to subpar print quality, cost inefficiencies, or delays in production.

To ensure a reliable 3D printing service, consider the following points:

-

Technical Capabilities: Not all 3D printers are created equal. Review the service’s technical specifications and capabilities, such as:

-

Printing resolution: A higher resolution means greater detail in the final print.

-

Material compatibility: Ensure the service can handle the material you intend to use.

-

Customer Service and Support: The ability of the service provider to handle queries and resolve issues promptly and effectively is critical. Consider:

-

Responsiveness: How quickly does the service respond to customer inquiries and issues?

-

Expertise: Does the service provide guidance and advice on optimizing your designs for 3D printing?

Advantages of Outsourcing to 3D Printing Services

Outsourcing to 3D printing services offers a myriad of benefits, including cost savings and access to advanced technology, which can significantly enhance the overall efficiency and quality of your production process. It provides an opportunity to leverage the expertise of specialists in 3D printing, eliminating the necessity to invest in costly equipment and training.

The primary advantage is cost-effectiveness. By outsourcing, you bypass the financial obligation of purchasing, maintaining, and upgrading expensive 3D printers. Furthermore, you save on operational costs such as staffing, training, and utility bills.

Another key benefit is the ability to access top-tier technology and skill. 3D printing services continuously update their software and hardware to stay competitive, ensuring you benefit from the latest advancements. Their dedicated staff possess specialized knowledge and experience, guaranteeing precision and high-quality outputs.

Scalability is also a significant advantage. As your business grows, 3D printing services can easily adapt to your evolving needs. This flexibility allows for increased production during peak periods without the burden of additional investment.

Lastly, outsourcing minimizes risk. It provides a safety net if your in-house printing capabilities fail, ensuring uninterrupted production. The combination of cost-efficiency, advanced technology, scalability, and risk management makes outsourcing to 3D printing services a strategic choice for businesses.

3D Printing Services: Cost and Time Frames

Frequently, the cost and time frames of 3D printing services are key considerations for businesses seeking to leverage this technology. The cost often varies due to factors such as material type, print volume, and complexity of the design. Similarly, the time frame can also fluctuate based on these variables, as well as the capacity of the service provider.

Cost Factors:

- Material: Different materials come with different costs. For instance, metals are more expensive than polymers.

- Design Complexity: Complex designs require more time and resources, increasing the cost.

- Volume: Larger prints command higher prices due to the increased material usage and longer printing times.

Time Frame Factors:

- Design Complexity: Intricate designs take longer to print.

- Volume: Larger volumes require more time to complete.

- Service Provider Capacity: The speed of the service provider’s machines and their workload can affect the completion time.

Understanding these factors is crucial for businesses to effectively budget for their 3D printing needs and schedule their projects. By choosing the right service provider and optimally managing these factors, businesses can maximize the benefits of 3D printing while keeping costs and time frames under control.

Case Study: Success With 3D Printing Services

In recent years, numerous businesses have achieved significant success by utilizing 3D printing services, as demonstrated by the following case study. A prominent automotive company, hereafter referred to as Company A, leveraged 3D printing to revolutionize their prototyping process.

Company A previously relied on traditional manufacturing techniques for prototyping, which were time-consuming and expensive. By adopting 3D printing services, they were able to drastically reduce their prototyping cycle from weeks to mere days and significantly cut costs.

Here is a comparative analysis in a tabular format:

| Key Aspects | Traditional Method | 3D Printing |

|---|---|---|

| Prototyping Cycle | Several Weeks | Few Days |

| Cost | High | Significant Saving |

| Flexibility | Limited | High |

These improvements led to faster iterations, enabling Company A to innovate more efficiently and stay ahead of the competition. This case study underlines the transformative potential of 3D printing services in modern manufacturing processes. By providing a faster, more cost-effective, and flexible solution for prototyping, 3D printing services are poised to become an integral part of the manufacturing landscape.

Future Trends in 3D Printing

Building on the recent advancements, the future of 3D printing promises to bring forth even more transformative trends in the manufacturing sector. Several key developments are currently on the horizon, each with the potential to revolutionize the industry.

-

Bioprinting:

-

Tissue Engineering: Bioprinting is expected to make significant strides in tissue engineering, potentially enabling the creation of complex biological structures.

-

Personalized Medicine: The technology could also facilitate the production of personalized medicine, tailoring drugs to individual patients’ needs.

-

Metal 3D Printing:

-

Aerospace and Automotive Industries: Metal 3D printing is predicted to find extensive applications in the aerospace and automotive sectors, where it can manufacture complex, lightweight structures.

-

Medical Implants: In the medical field, metal 3D prints could be used to create customized implants with superior fitting and functionality.

These trends indicate an exponential growth in the capabilities of 3D printing technologies, expanding beyond prototypes into functional, end-use products. As we continue to innovate and refine these technologies, we edge closer to a future where 3D printing becomes a mainstream manufacturing tool.

This progress also prompts us to consider the environmental impact, leading us into our next topic of discussion: 3D printing and sustainability.

3D Printing and Sustainability

Transitioning from trends in the industry, we now delve into the important facet of 3D printing and sustainability, a subject that has grown increasingly crucial as the technology continues to evolve and expand.

The relationship between 3D printing and sustainability is multifaceted, encompassing issues of materials usage, energy consumption, and waste reduction.

3D printing has the potential to reduce material waste significantly. Conventional manufacturing methods often involve subtractive processes, where a large portion of material is discarded. In contrast, 3D printing is an additive process, using only the material necessary to create the product. This not only minimizes waste but also reduces the need for raw material extraction, thus decreasing environmental impact.

Energy consumption is another sustainability concern. While 3D printing operations require electricity, studies indicate that it’s less energy-intensive than many traditional manufacturing processes, particularly for small-scale production.

However, the sustainability of 3D printing is not without challenges. The majority of 3D printed objects currently utilize thermoplastics, which are not biodegradable. Developing environmentally friendly materials for use in 3D printing is therefore a critical area for future research and innovation.

Legal and Safety Considerations in 3D Printing

While the sustainability of 3D printing presents its own unique challenges, it’s equally important to consider the legal and safety implications of this technology. The advent of 3D printing has raised significant questions around intellectual property rights, product liability, and safety standards.

Legal Considerations

-

Intellectual Property Rights: With 3D printers, people can easily reproduce patented products, potentially infringing upon existing patents and leading to complex legal battles. The nature of digital files also makes them easy to distribute, exacerbating potential infringement issues.

-

Product Liability: Determining responsibility in the event of a product failure becomes more complex with 3D printed products. Is the liability with the designer of the file, the printer, or the individual who printed the item?

Safety Considerations

-

Material Safety: Some materials used in 3D printing, such as certain types of plastic, can release harmful fumes or residues. Proper ventilation and handling protocols should be in place.

-

Equipment Safety: 3D printers involve high temperatures and moving parts, posing potential hazards. Safety standards and guidelines need to be established and enforced.

The legal and safety landscape surrounding 3D printing is still evolving, necessitating ongoing vigilance and proactive measures by all stakeholders.

The Impact of 3D Printing on Jobs and Economy

Despite the legal and safety challenges that must be navigated, the rise of 3D printing technology also offers significant implications for the job market and the broader economy. Its potential to revolutionize manufacturing processes may lead to an increase in jobs requiring specific technical skills, while potentially eliminating others.

| Potential Impacts | Economic Sectors |

|---|---|

| Job creation | Technology, Engineering, Design |

| Job elimination | Traditional Manufacturing |

| New business models | Retail, Healthcare, Construction |

This disruption provides opportunities for new business models, particularly in industries such as retail, healthcare, and construction. However, it also threatens jobs in traditional manufacturing sectors, as 3D printing could replace some current processes.

The economic implications of this technology are equally profound. With its ability to produce goods locally and on-demand, 3D printing could reduce costs in logistics and inventory management, leading to significant savings for businesses. Conversely, it may also impact global trade, as fewer goods need to be transported internationally.

Frequently Asked Questions

Can I Use a 3D Printer at Home and if So, What Safety Measures Should I Take?

Yes, home use of such technology is possible. However, safety measures are essential, including ensuring adequate ventilation to limit particle exposure, using correct handling procedures for materials, and maintaining the equipment properly to prevent malfunctions.

How Long Does It Typically Take to Print an Object With a 3D Printer?

The duration to print an object greatly varies based on its size, complexity, and the printer’s speed. Typically, smaller objects may take a few hours, while larger, intricate designs could require multiple days to complete.

Are There Any Specific Skills or Qualifications Needed to Operate a 3D Printer?

Operating advanced machinery typically requires a certain level of technical knowledge. For using this specific device, understanding of CAD software, material properties, and basic machine operations, combined with hands-on training, is highly beneficial.

What Are Some Common Mistakes Beginners Make When Using a 3D Printer for the First Time?

Navigating through the labyrinth of new technology, beginners often stumble by not calibrating the device correctly, misjudging print speed, or neglecting the importance of the print bed’s temperature and level for optimum output.

Is There Any Specific Maintenance Required for a 3D Printer?

Yes, specific maintenance is required for optimal performance. This includes regular cleaning, lubricating moving parts, tightening screws, updating software, and checking the print bed and extruder for wear and tear.

Conclusion

In conclusion, 3D printing technology has created a significant paradigm shift in various sectors, from manufacturing to healthcare. As the technology evolves, it will continue to influence sustainability, job creation, and economic stability.

However, it necessitates careful consideration of legal and safety aspects. Embracing this innovative technology calls for a comprehensive understanding of its operation, the different types, materials used, and anticipating future trends.